|

After looking for an off the shelf exhaust system that

would fit

my requirements and not finding a good match I decided to give Aircraft

Exhaust Inc. a call about their design your own Custom Exhaust

System.

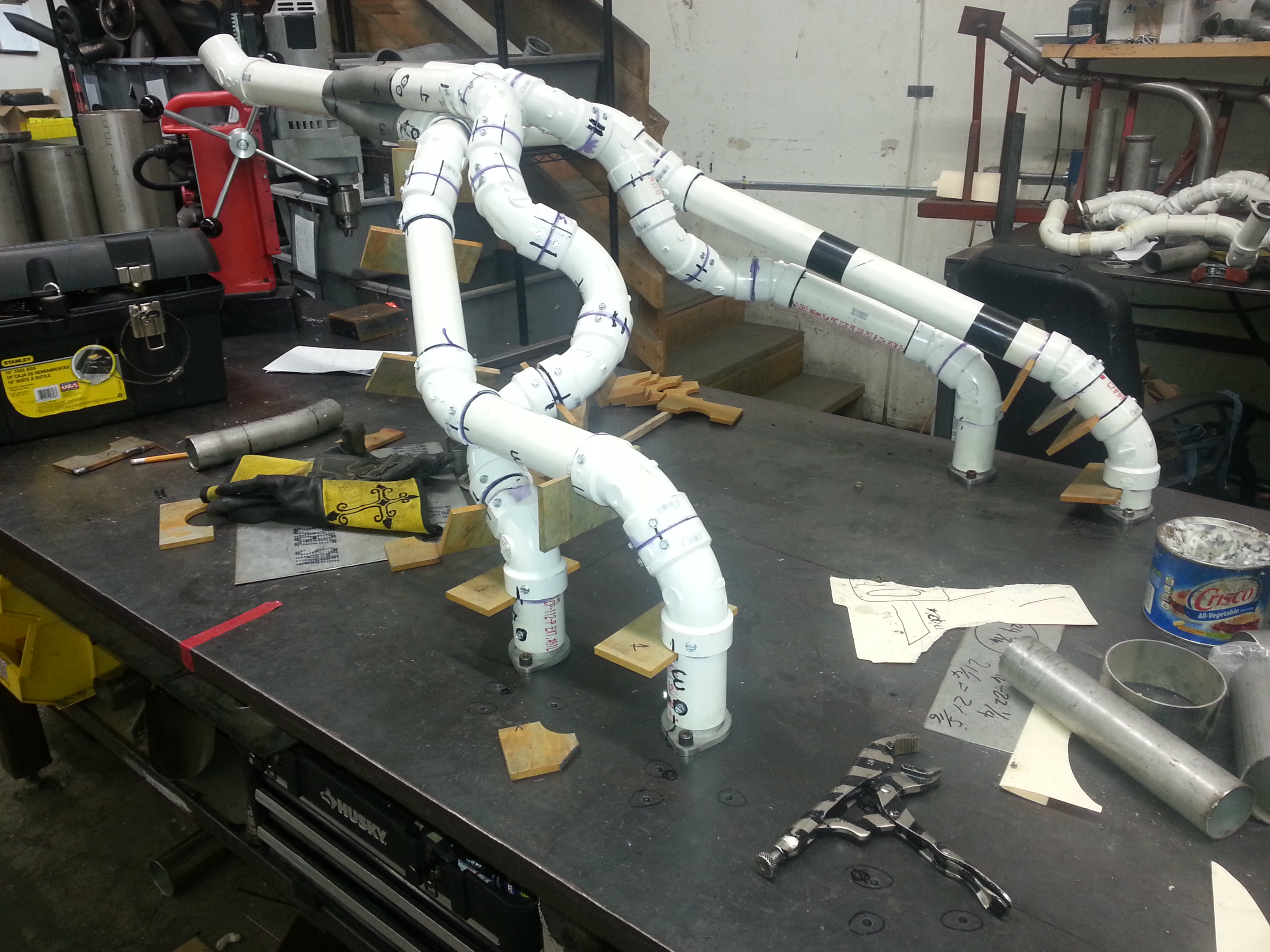

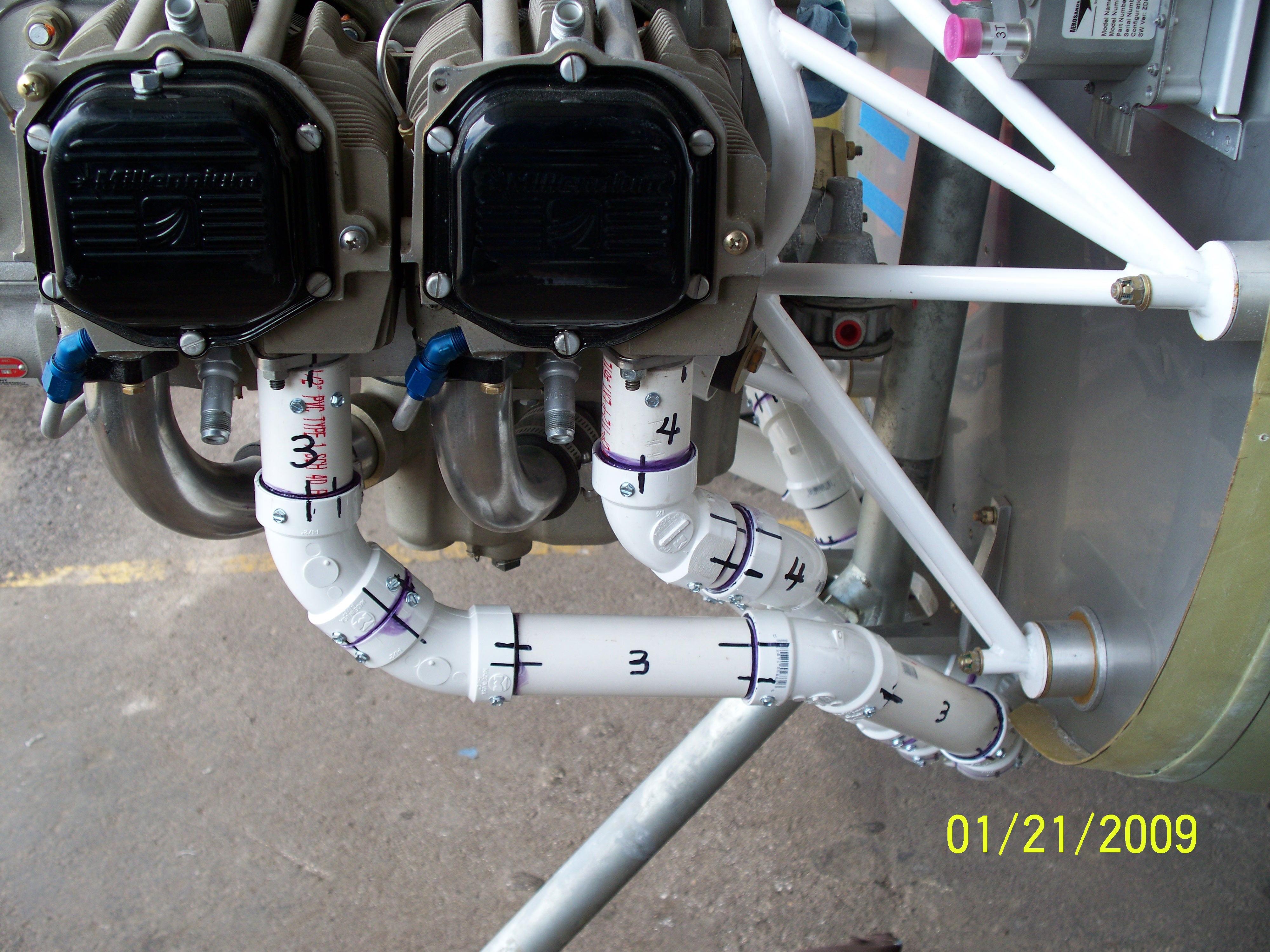

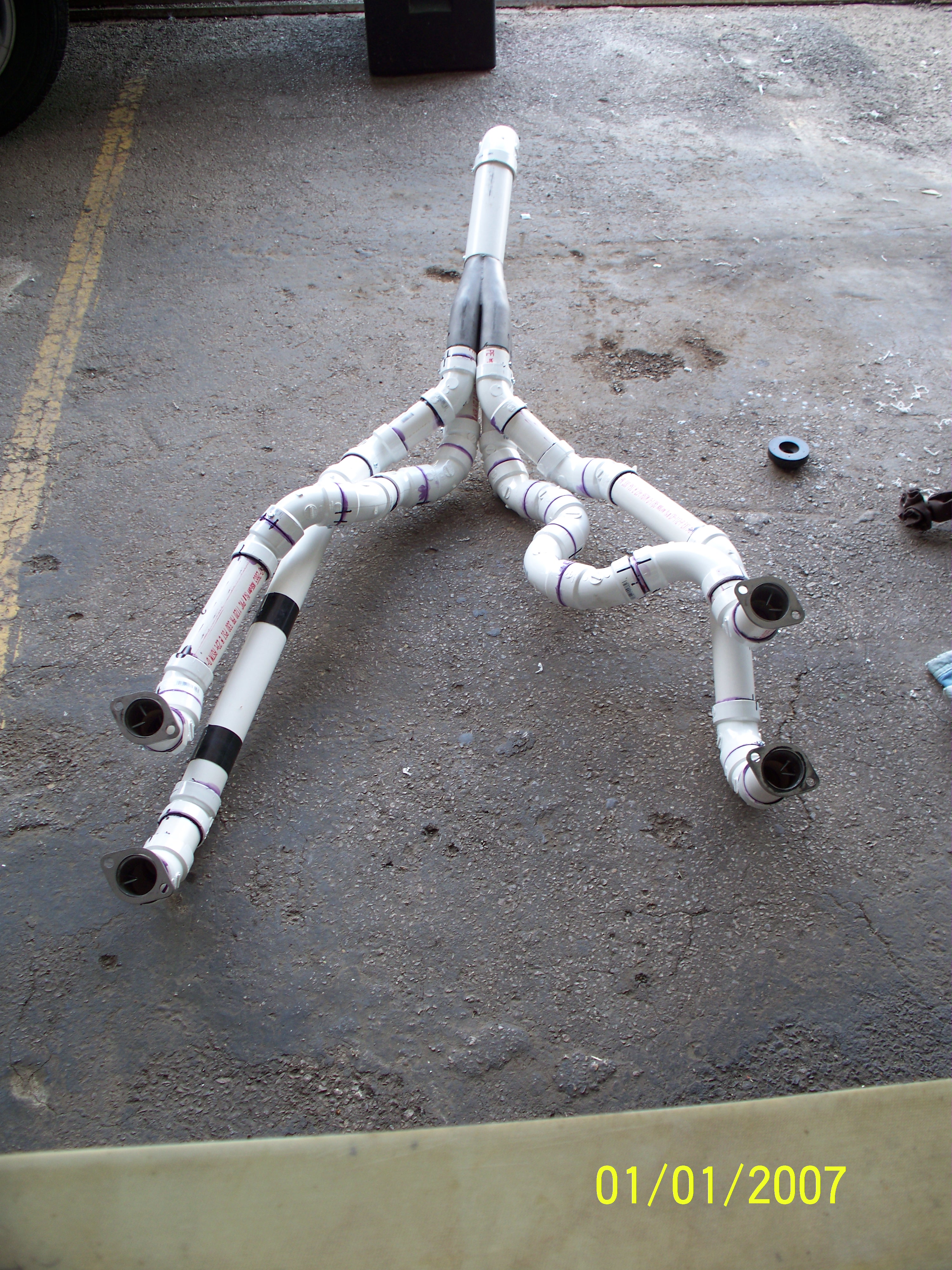

The process starts with obtaining a collector

based on your requirements and the

exhaust port connectors from the custom exhaust manufacturer. You

supply the

necessary PVC pipe and joints to custom design a system to your exact

requirements. The following show the completed mockup to be sent

for

fabrication.

While I was working on the fabrication of the

system a couple of other

pilots who have planes on the field where I have my hangar stopped by

to

see what I was doing. One of them was familiar with the process

and

started discussing it with me. The other had absolutely no idea

of

what I was doing...only that I was building my exhaust out of plastic.

Finally after about 10-15 minutes he couldn't take it any longer

and

asked "Aren't you afraid that your exhaust will melt?". I thought

his

friend was going to laugh himself sick. We finally explained that

this

was just a mockup and it would be used to build a stainless steel

version.

|

|

|

|

| A trip to Home Depot resulted in a

good supply of 90, 60, 45, and 22.5 Degree PVC connectors and several 2

foot lengths of PVC pipe. Get more than you will need, you can

always take some back. |

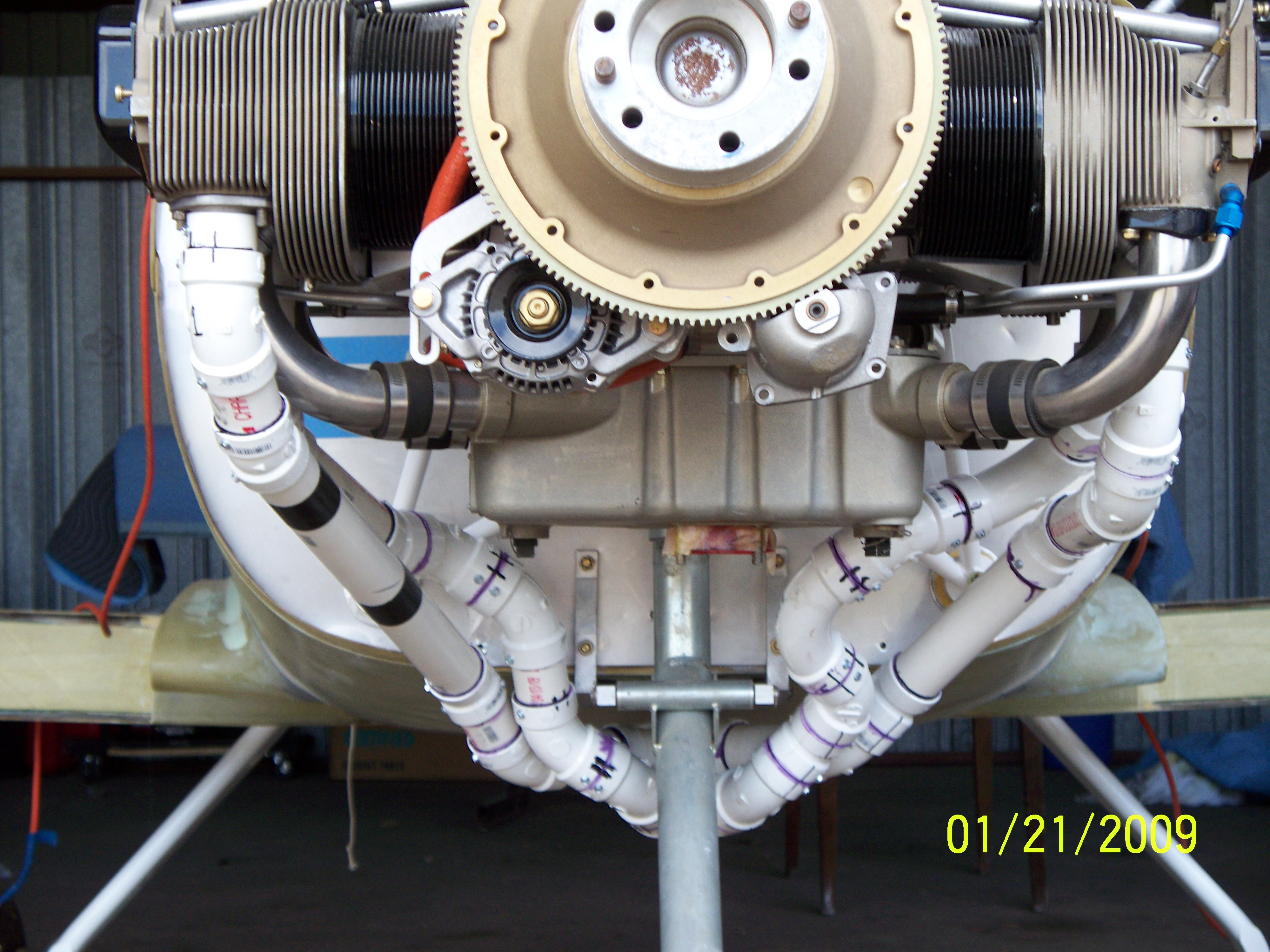

Start by mounting the collector

where you want it to be positioned when complete. It must be

placed and held firmly in position while working on the assembly.

The process will take lots of fitting and refitting. |

|

|

|

|

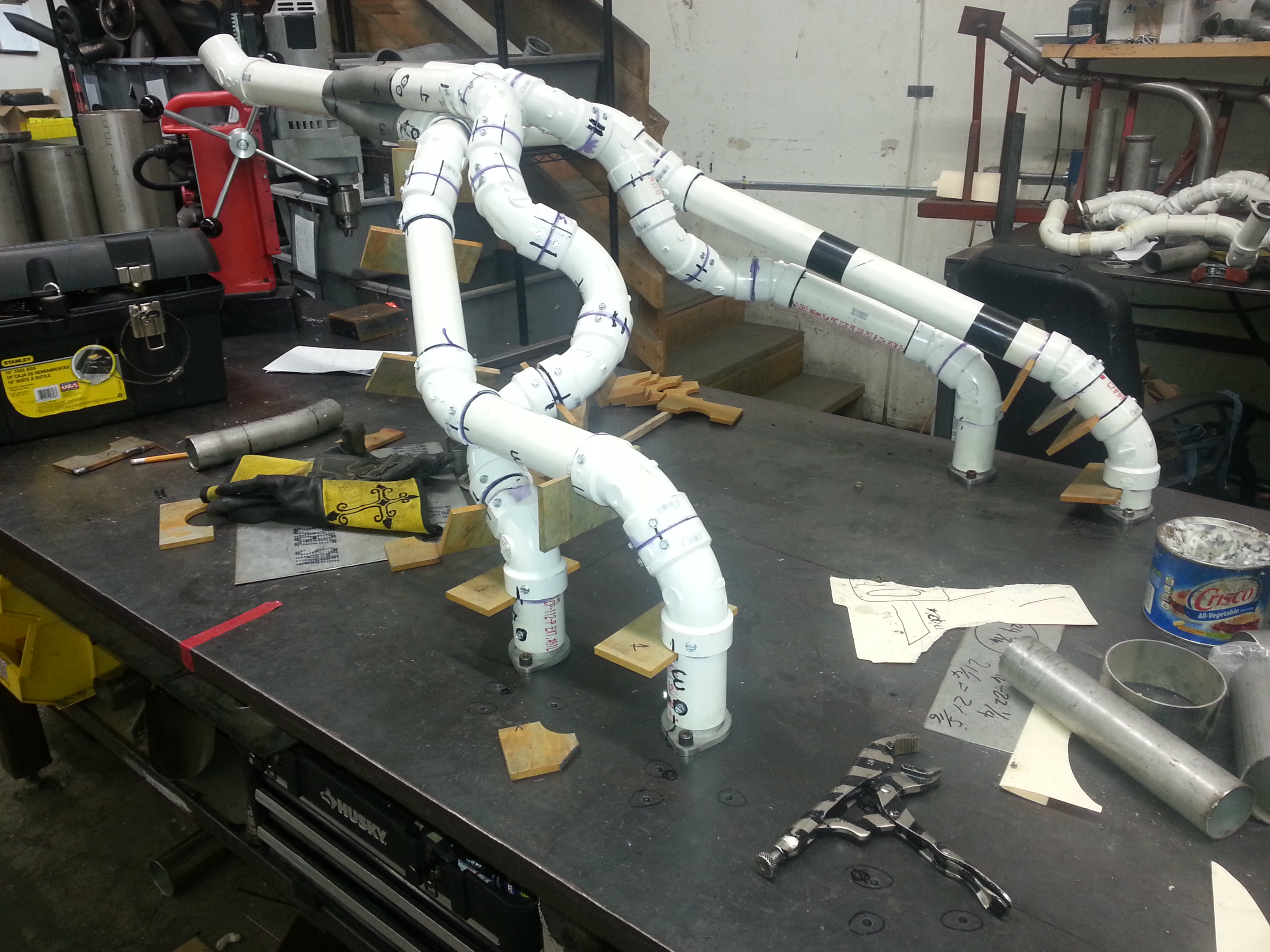

| The above is the completed mockup

before gluing all the componets together. |

The length of the individual

exhaust pipes are all within 1 inch of each other. |

|

|

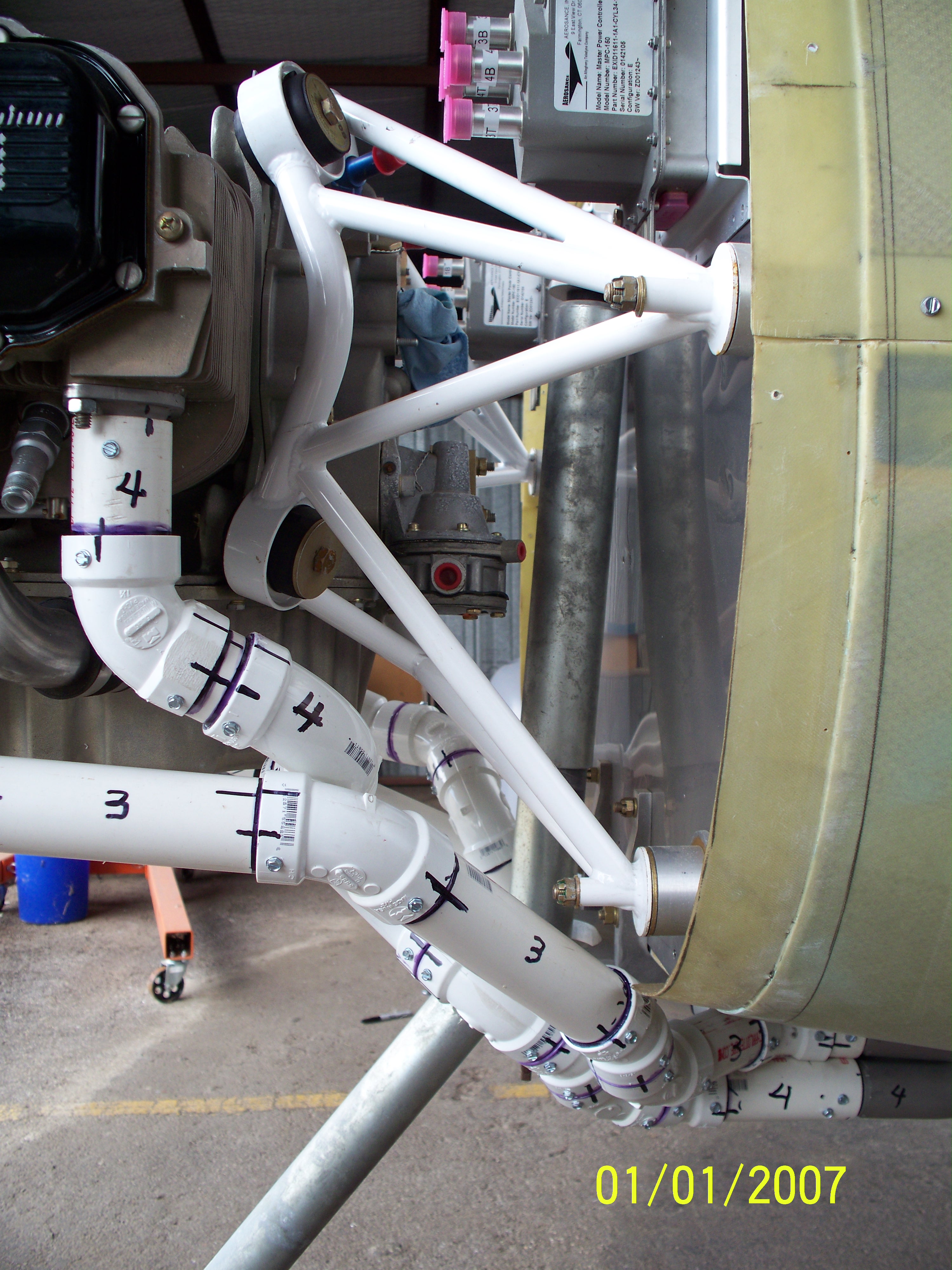

| The number 4 pipe takes several turns that don't appear to

be needed but are there to equalize the length. |

I had to assemble, disassemble, and rework several times

to

equalize the lengths. Time consuming and frustrating. |

|

|

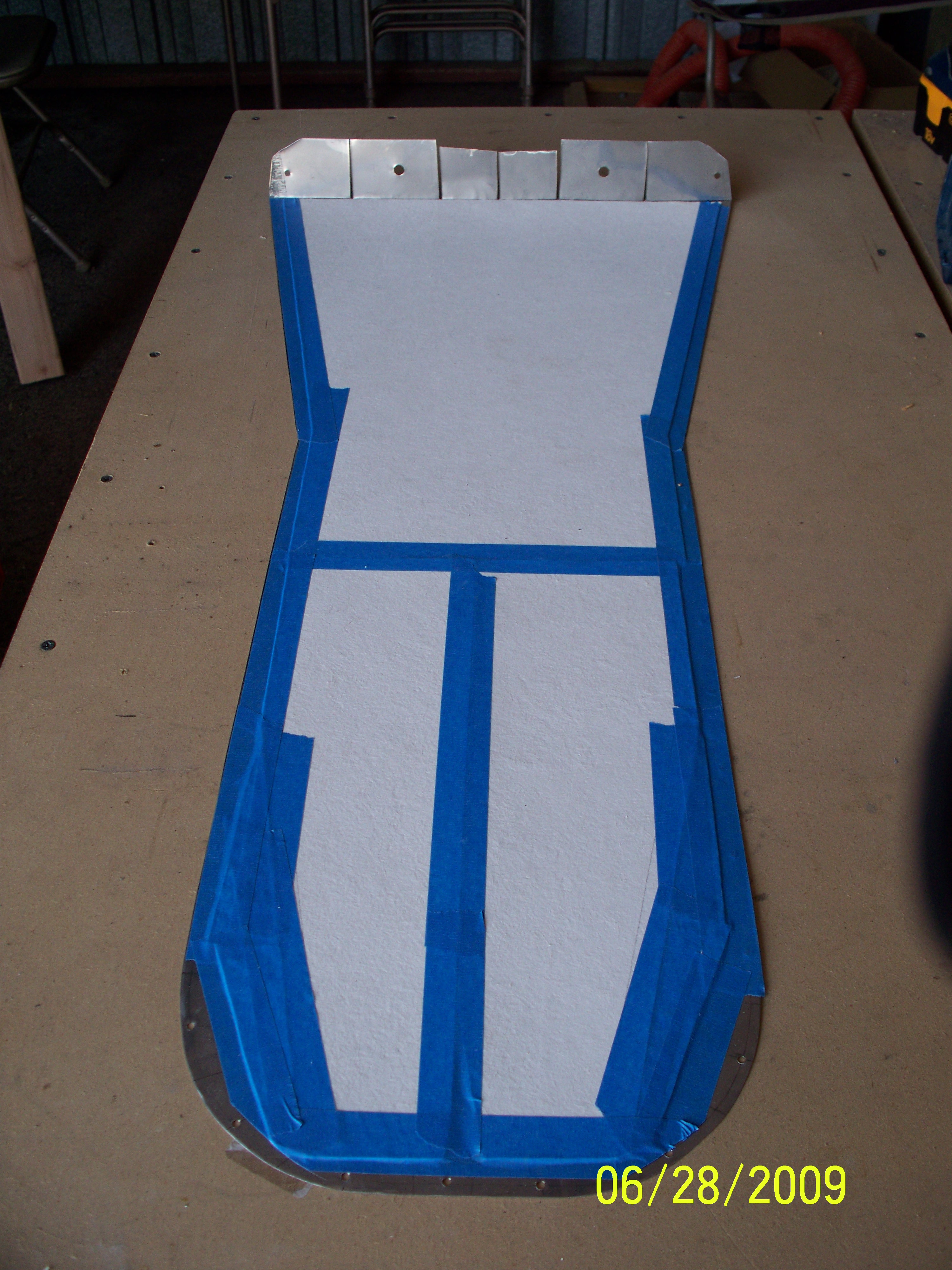

Once all the pieces were cut to the proper

length and dry fit into the collector they had to be marked to identify

how they went to gether and which pipe was which. The entire

system would then have to be disassembled yet again. Each piple

would then be reassembled using PVC Cement and screws to lock all the

pieces into their proper position for shipment. Once everything

was glued into place it was fully assembled again to make sure

everything fit as designed.

|

|

|

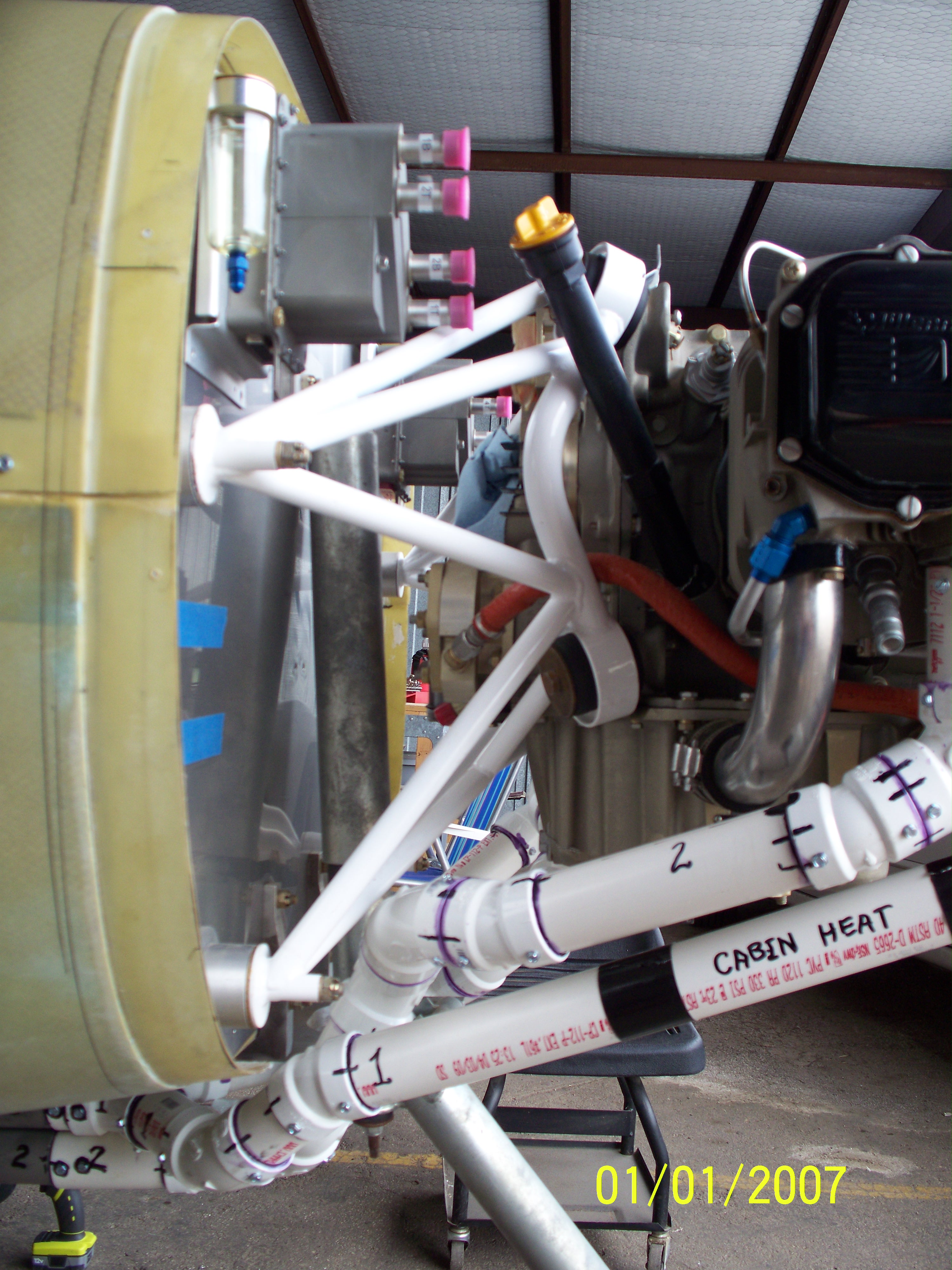

| The heat muff for cabin heat

will go where shown. |

If needed, carb heat could be

place on the other side. |

|

|

|

|

|

|

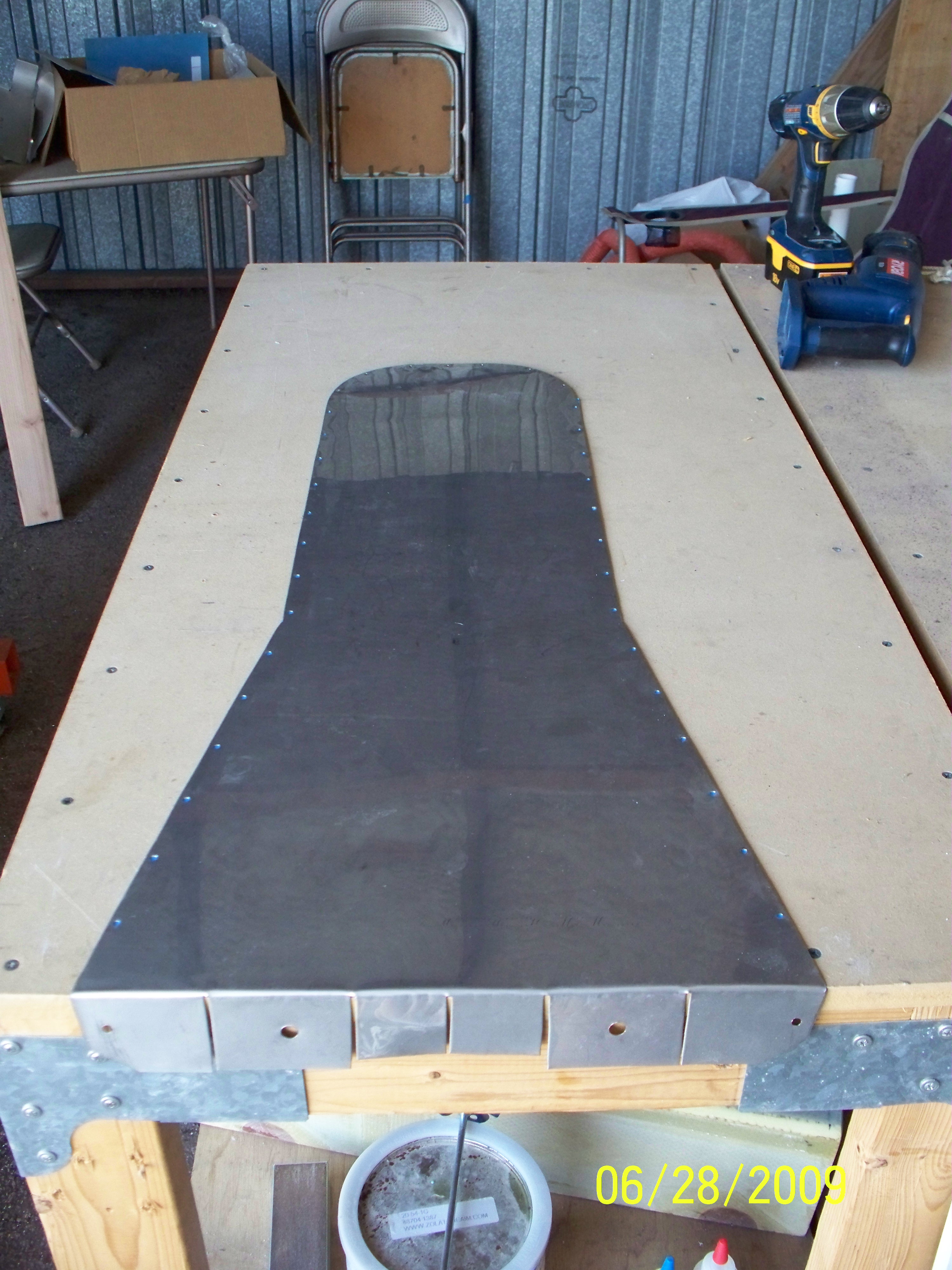

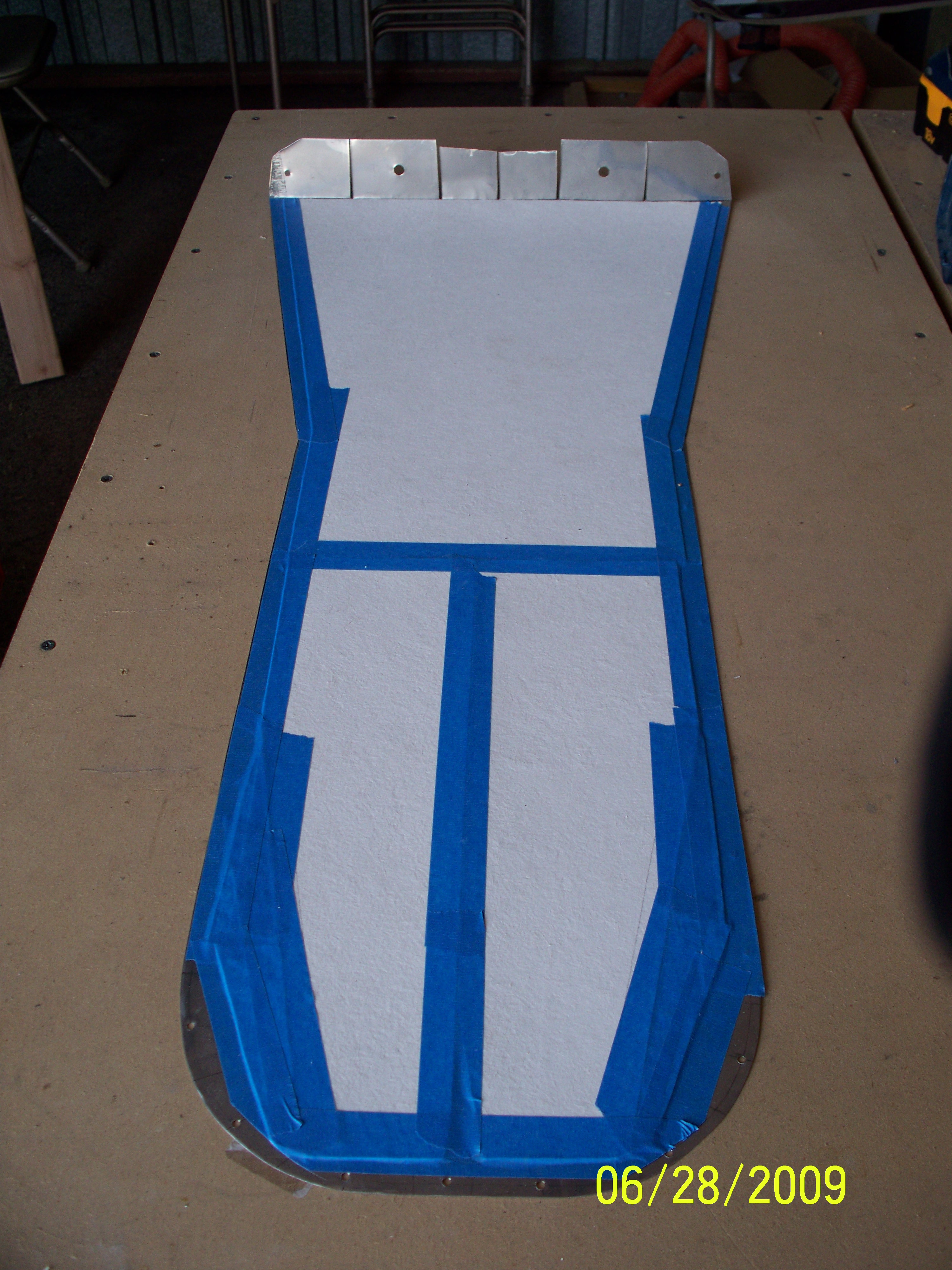

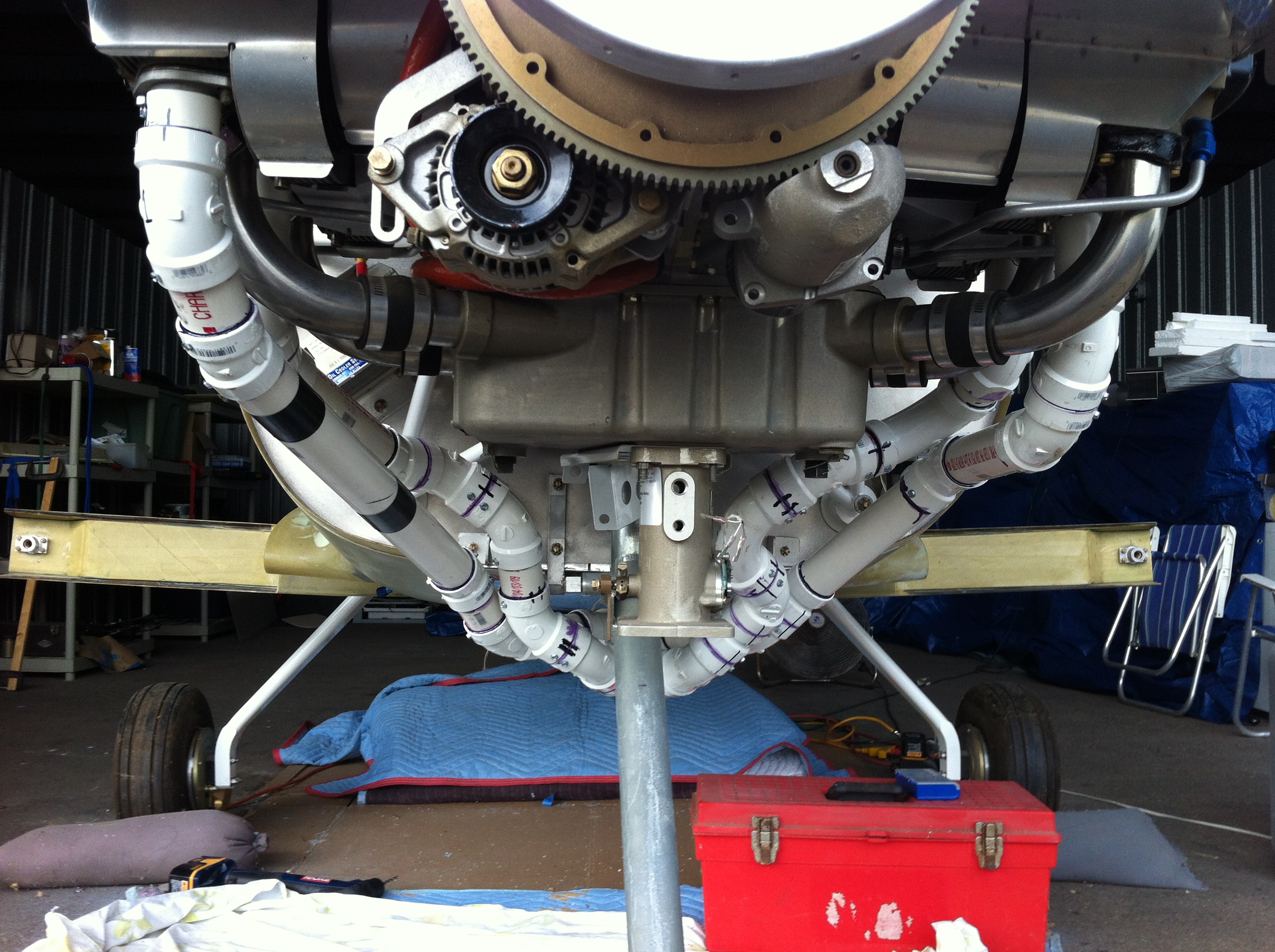

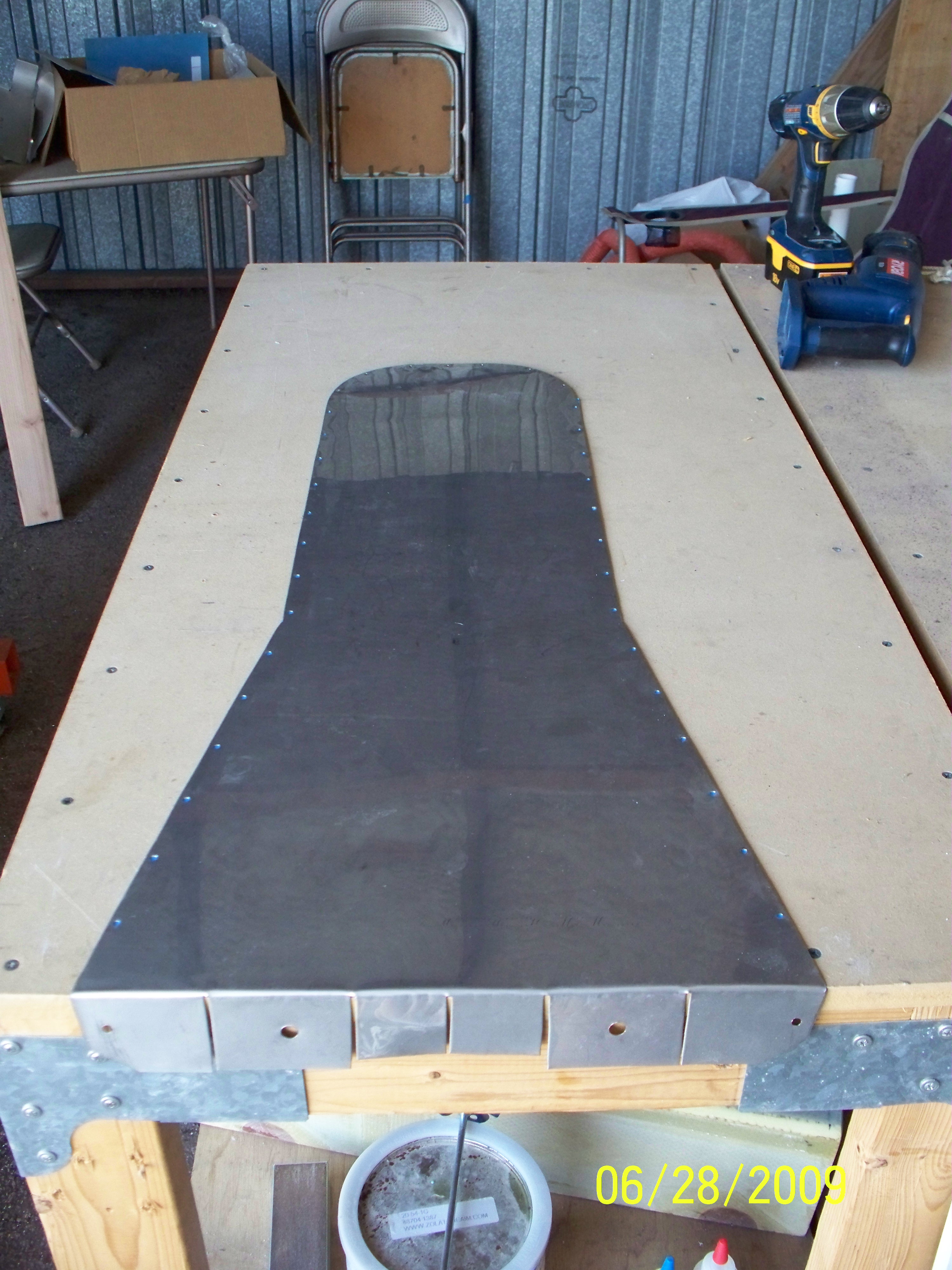

The underside of the fuselage along the Center will have a

stainless steel panel with fiberfax backing installed. |

The fuselage panel will protect the fuselage from any

exhaust heat.

|

|

|

Care must be taken to ensure clearance between exhaust

components and anything that might damage them. |

Or any components which might be damaged by the hot exhaust

pipes. |

|

|

|

|

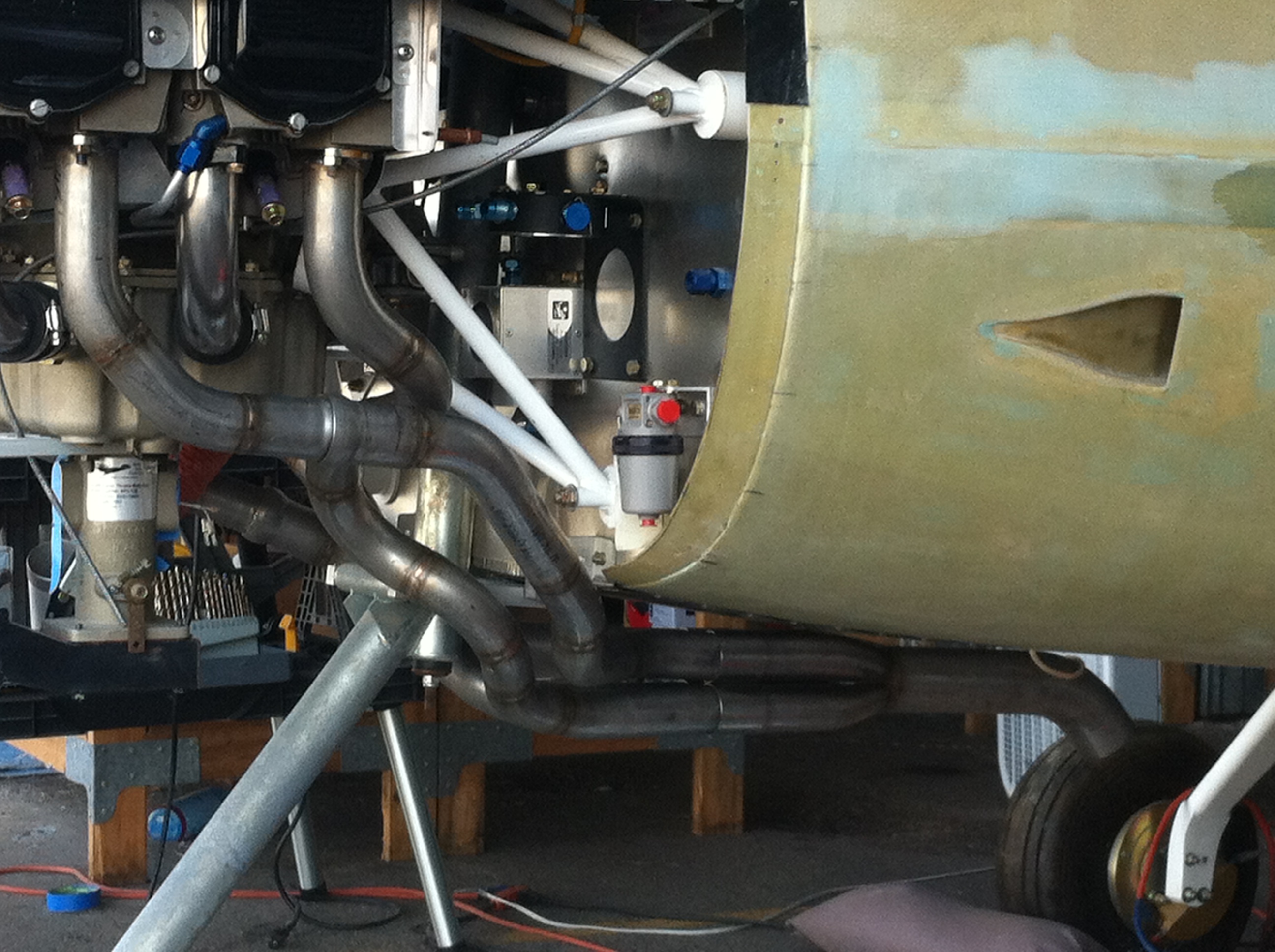

The above show the

routing of the system between the engine and the underside of the plane.

|

|

|

| The view from the side shows how closely the cowling fits

and how far back the full system will go. |

Some adjustments will be needed to the cowling to provide

more space from the exhaust pipes. |

|

|

The completed mockup is glued together and ready to be

disassembled at the collector for shipment. |

When removed from the engine, the mockup retains its shape

exactly as formed. |

|

|

I was concerned having a large portion of the HOT exhaust

system under the fuselage and what effect that head might

have on the Fiberglass structure. |

My solution was to fabricate a protective belly pan from

the same stainless steel material used for the firewall. I also

lined it with the fiberfax used on the firewall. The tape just

holds it in place. |

|

The installed belly pan is shown in place on the underside

of

the fuselage. It extends back beyond the tail pipe extensioin and

far enough that I could include a short muffler beyond the 4-into-1

collector. This should provide complete protection for the

underside of the fuselage. The pan is currently being held in

place with pop rivits. I will probably add some glass and filler

to dress up the edges and provide additional holding power. |

|

|

These photos show the mockup on the

fabrication table as they began construction of the system. The

remainder of the photos show the trial fitting of the complete

system. It really looks good and fits exactly as designed.

|

|

|

|

One

big issue I encountered with the exhaust system was how to lock the

four-into-one section on to the four individual exhaust pipes.

The section slides onto the four pipes but didn't seem to go all the

way on and nothing I could do would slide it on farther. Each

pipe goes in about an inch but I thought it could go on farther.

Another problem was how to support the weight of the pipes and still

allow movement with the engine. My final solution to both

problems was a rather odd bracket and strap system that connects to the

fuselage at two points with thick rubber straps to a bracket attached

to the rear of the pipe. The idea is to both support the pipe and

keep it from sliding backwards.

|