| The KIS Cruiser

Kit, like many other homebuilt aircraft kits,

can be started

with the horizontal stabilizer and elevator kit. Often this

portion

of the kit can be purchased separately and used as a test kit to

determine

if you are really interested in, and have what it takes to build an

airplane.

It also provides an opportunity to see if you are going to feel

comfortable

with the construction techniques.

The elevator top and bottom are molded together with

the stabilizer.

They must be cut into separate pieces along scribe lines formed

into

the molded parts. The details of this process are outlined in the

first

part of the section on the Horizontal Stabilizer. |

|

|

|

The Horizontal Stabilizer and Elevator come

as two molded parts, an upper skin and a lower skin. There are

score lines on the parts that identify the separation lines for

separating the elevator from the horizontal stabilizer parts.

|

|

The

separated parts identify the separation points for the division of the

elevator into two parts between the rudder section.

|

|

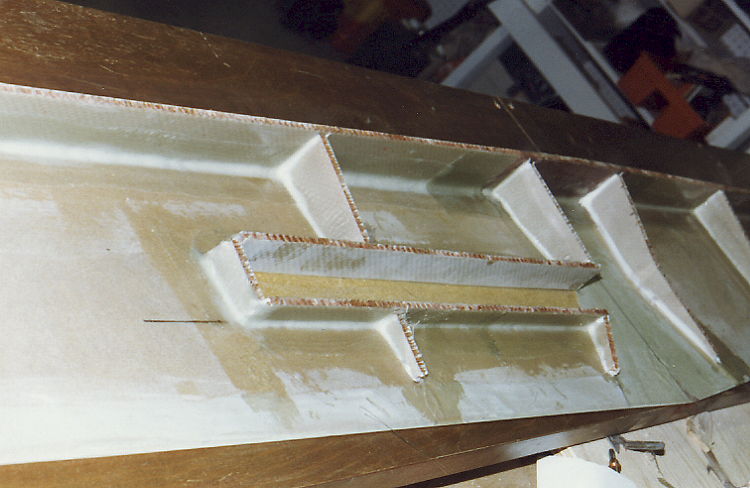

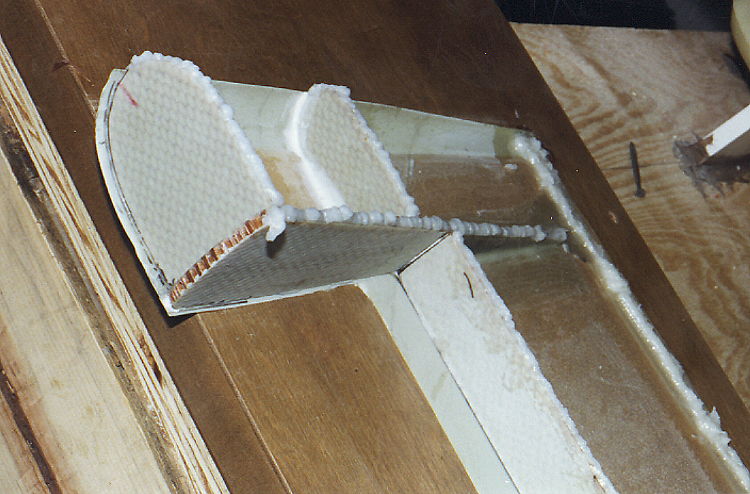

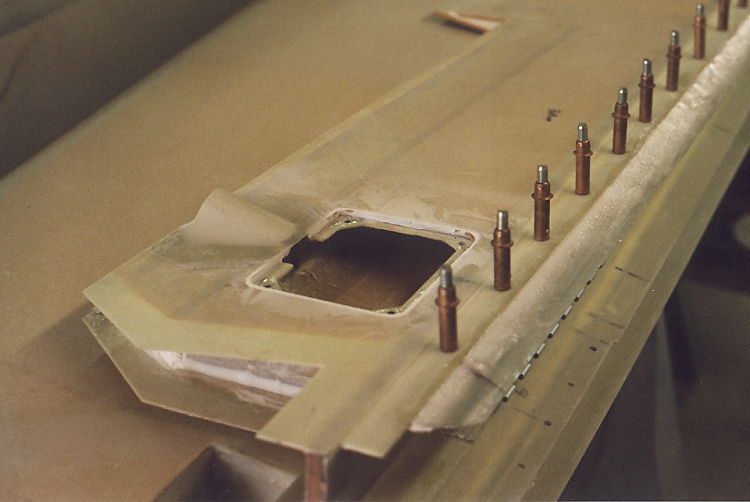

The elevator is prepared by mounting the top to a flat

surface using bondo or 5-minute epoxy.

The elevator spar and ribs are prepared and bonded

and glassed in place.

|

|

The basic spars for the trim tab are also put into

place. (Those of you who have completed their elevators will

notice a major mistake in the size and position of the trim tab on the

this photo. I read the instructions wrong and the trim tab is

much larger than it should be. I caught the mistake after I had

closed out the elevator but before cutting the trim tab out. I

went ahead and cut it to the correct size and made the subsequent

repairs.) |

|

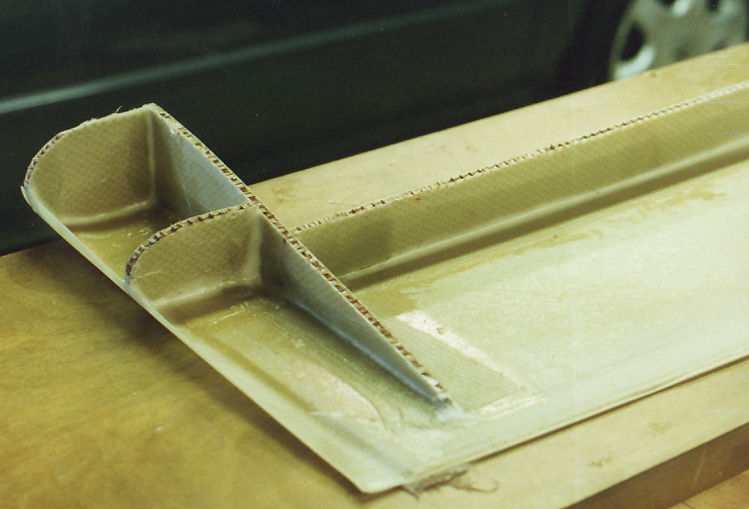

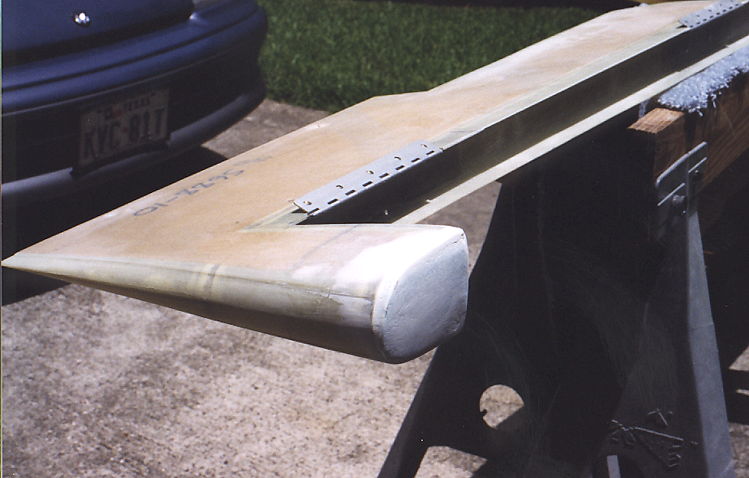

This photo shows a slight modification I made to the

instructions. I closed out the end of the counter weight before

closing the elevator. This gave a very secure chamber for holding

the counterweight lead. I then shaped the end of the counter

weight with foam and glassed it over with two ply bid. Worked

very well. |

|

|

|

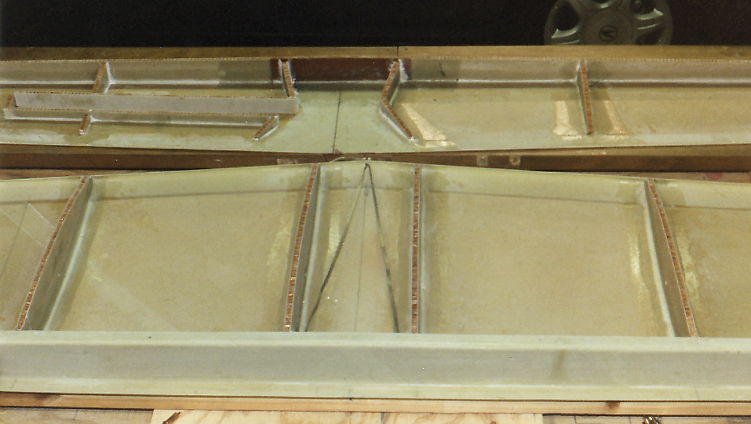

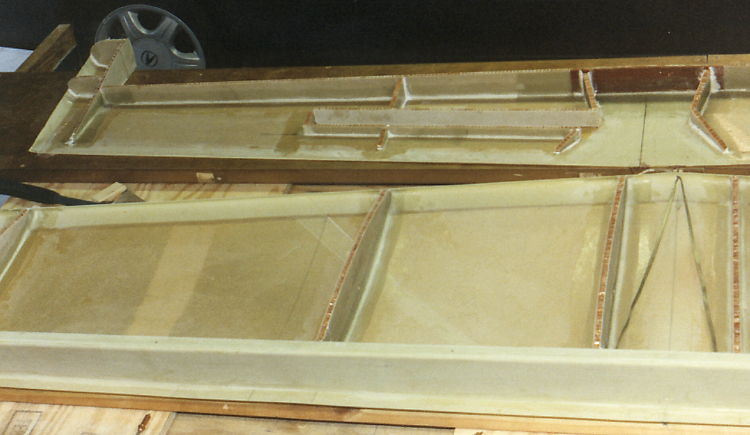

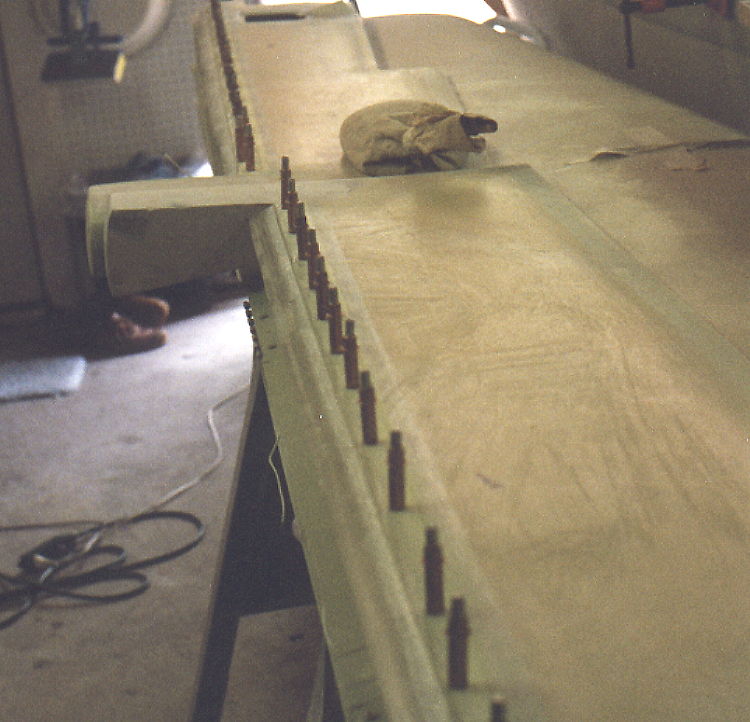

The above photos and left show the horizontal and vertical

stabilizer both ready for closeout. |

This photo, and the one on the right show the space

in

the prepreg and trailing edge of the elevator filled with epoxy-flox.

I smoothed out epoxy-flox to form a uniform bede and closed

out the elevator.

|

|

|

A lot of weight,(a bundle of shingles is very heavy)

clecos, a few shims, clamps and a lot of patience and the elevator and

horizontal stabilizer are close out. (Notice how neat, clean and

uncluttered my workshop is. It may look bad, but it works OK.)

|

|

|

| This view shows the shape of

the elevator counter weight during initial shaping. Some

additional shaping was done prior to final glassing. The result

is very narrow gaps and a very clean look. |

The trim tab shown with the

full elevator. This is the correct size and spacing for the trim

tab. I used a full width piano hinge to join the trim tab to the

elevator. I also used pop rivets centered on each hinge tab to

join the tab. This was taken just before separating the two

halves of the elevator. |

|

|

|

The inside

edges of the trim tab had to be reinforced with a layer or two of glass

to provide for mounting the hinge for the trim tab.

|

|

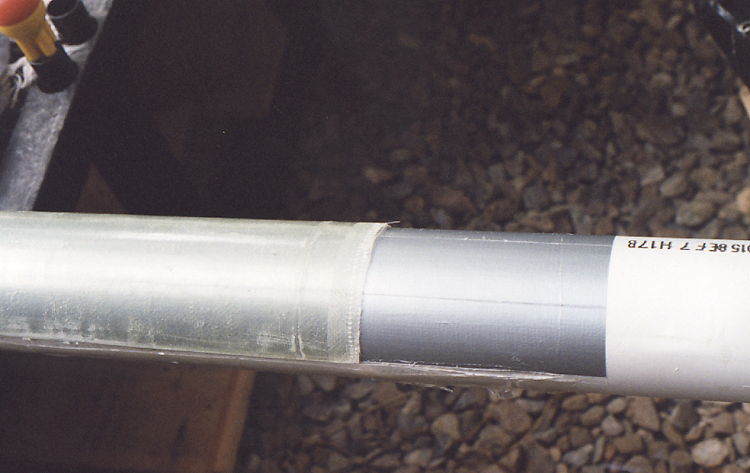

I wasn't sure but decided to

make a layup over some 3 inch PVC pipe and see if I could make it work.

I also thought that this would make a good cover for the flap

control tube. Both worked.

Using the good old trusty duct tape, I put several lengths

down the PVC pipe and covered with a length of prepreg glass. A

little peel-ply, some time and I had some nice curved sections of

fiberglass. |

|

I made two length of the

curved glass. I cut one of them lenghwise into strips about two

and 1/2 inches wide. The photo shows the strip after I bonded into

place using the clecos to hold in place. After bonding, I filled

the edge in, sanded and added a single ply of glass to blend and add

strength. The surface was very smooth and worked out very

well.

|

The curved edge is bonded into place and can be seen in these two

photos. The cleco holes were filled and a final layer of glass

added to give a smooth edge.

|

|

|

Once the curved edge was

finished, I checked for proper elevator travel and found that I had to

sand the edge down some to get the required down travel. I also

found that the edge now gave a positive control stop.

This photo shows the opening for the trim servo and the

fairing for the servo controls.

|

|

The

completed elevator sides have been primed and ready for painting.

They have been balanced with the trim servo installed and should be

very close to a perfect balance once painted.

|

|

The

elevator has been completed, painted and installed. The control

movement is very smooth and light. The trim tab can just barely

be seen. The hinges are installed with the screw heads recessed

and glassed over to produce a clean surface between the horizontal

stabilizer and the elevator. Extra layers of glass were installed

on the hinge pads to account for the recessed screws.

|