Once the fuselage

is level and anchored, the first operation is to get

the firewall cut and mounted. This operation is probably the

single

best reason for the fast build kit. The plywood which I received

with

the kit had both warped and bowed which required some real work to get

it

right. I first cut and shapped the firewall close to the final

shape.

Next, I glassed the face with a single bid and placed the panel

between

a 3/4 inch plywood board and a very solid and flat glass panel and

weighed

it down. This seemed to work fairly well and got rid of some of

the

problem. The panel warped again during installation however and

required

additional work to get straight.

|

|

|

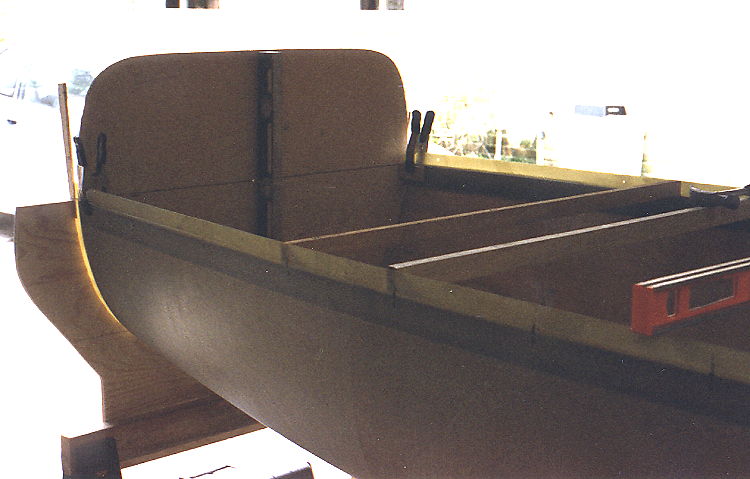

Vertical level for sitting firewall. Note the

fuselage spacers to hold fuselage shape. |

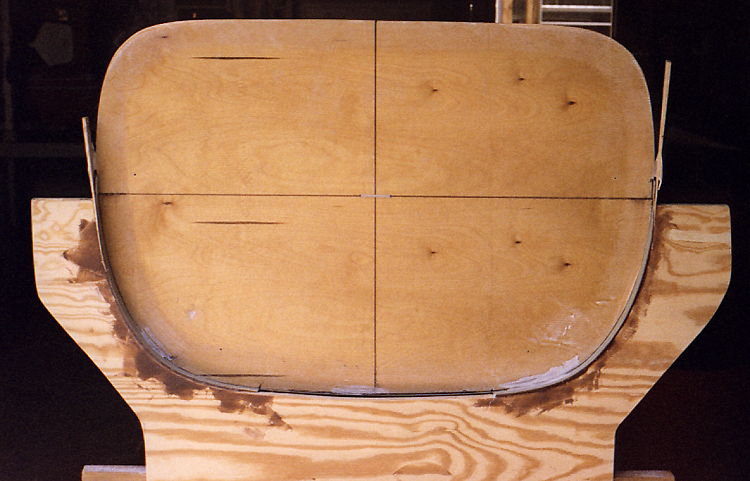

Firewall cut and shapped with horiz & vert

alignment lines. Initial bonding operation. |

|

|

Squaring the firewall to the fuselage. I used

an 8 ft. straight edge to improve accuracy. |

The bonding of the firewall is complete on

the front side and now ready for inside. |

|

|

| Firewall has been initially bonded into place and bracing

tacked in place. |

Note the horz and vert alignment lines. The

two holes are for nylon strap to hold tape

measure for one handed measurements. |

Once the firewall is correctly positioned and squared, plywood

braces

are positioned and these are then glassed into place. Each of

the

lower braces are positioned just inside of the engine mount holes.

The

upper bracing brackets the upper engine mounts. The cross brace

adds

support for the nose gear. The glass work for the inside of the

firewall

is probably the most difficult you will do. This involves

multiple

layups with the individual layups having multiple overlaps.

|