|

To keep the fairing from fitting too tight and making

subsequent installation and/or removal of the wing a real problem, I

put three layers of duct tap over the wing joggle. This should

provide enough spacing to allow a small clearance that can be covered

by a gap seal.

You can also see the line I used for placement of the

angle of incidence jig.

|

|

I found it best to position the lower fairing in position

setting on the edge of the flap and taped under the fuselage. |

|

I don't know how I could have done this without duct tape.

I was just sticky enough to hold the pieces in place if you could

find enough hands to hold the parts and tape at the same time.

The tape did allow for placement and removal and adjustment as

needed. Once the position is determined I installed screws to

hold it inposition. |

|

The Right wing fairing is in position and and I've started

to install the screws that will both hold it in position during bonding

and clamp it against the fuselage for bonding. |

|

Part of the trial fit of the wing fairing is fit the

fairing to the trailing edge through the length of the wing. The

trailing edge should be even along the entire edge when the flaps are

fully retracted and the aileron is in the neutral position.

All the gaps, 1/16" between ailerons, wing tip and flaps,

were very consistant and the fit was great. The space between the wing

and flaps is tight but non-binding. I do wish I had reduced the

hinge gap from 1/8 inch to 1/16".

|

|

The screws next to the flap are needed to hold the bottom

and top of the fairing together. I will lower the flaps during

the bonding and use a 1/2 wood strip on the underside to screw into.

This should help hold a constant pressure on the entire length. |

|

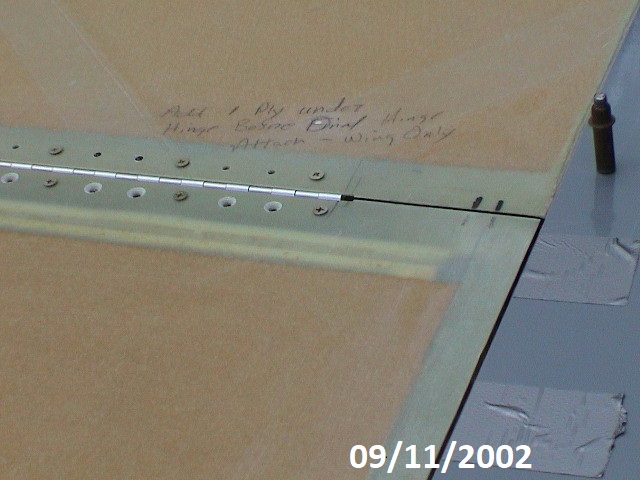

During the trial fit up I found that the aileron was just

slightly high and that one flap was slightly low. I made note on

the wing to add a one ply bid under the hinge to act as a shim and

effectively lower the aileron.

One aditional note: I used a longer hinge than

called for in the builders manual and placed the screw holes at the

strongest portion of the hinge every inch. That's more screws and

they don't line up. I will countersink the screws , bond them in

place and fill the holes. I use removable hinge pins for removing

the ailerons and flaps.

|