The Vertical

Stabilizer is comprised of two premolded components which are joined

together forming the upper portion of the rear fuselage, the dorsal

fin, and the vertical stabilizer.

|

|

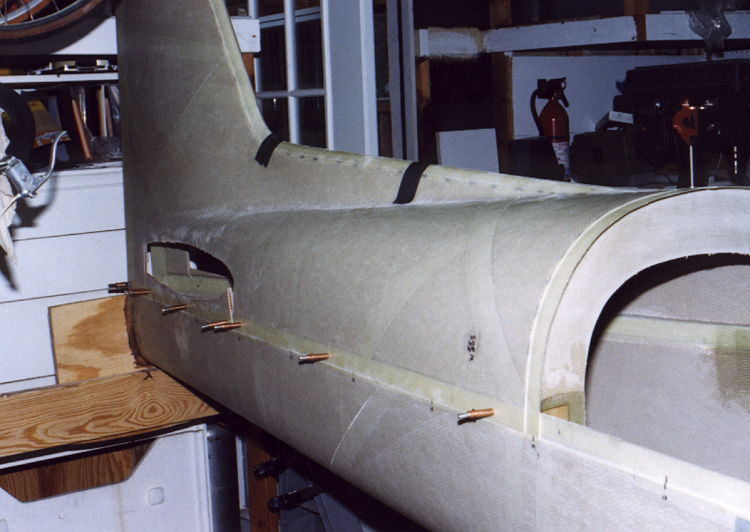

Trial fit of the vertical

stabilizer prior to installation of the horizontal stabilizer.

The cutout for the horizontal stabilizer has been made and the

supports for the horizontal stabilizer are also shown temporarily in

place. I recommend holding onto those cutout portions and using

them for filler once the horizontal stabilizer is installed. |

|

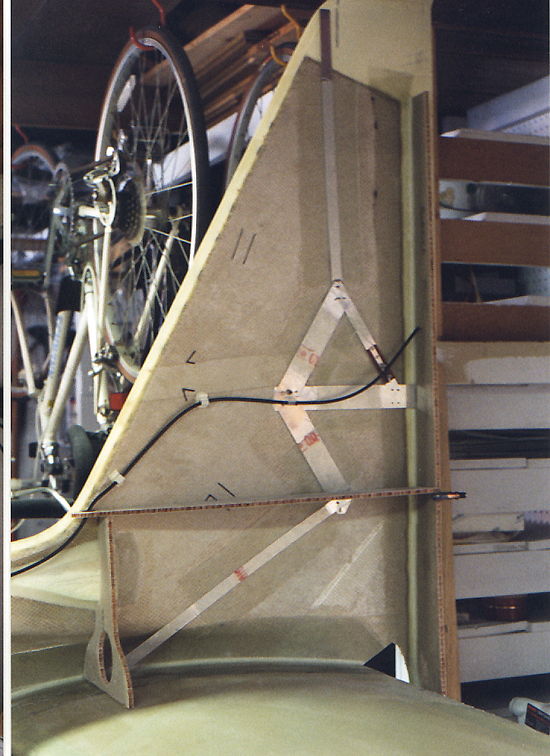

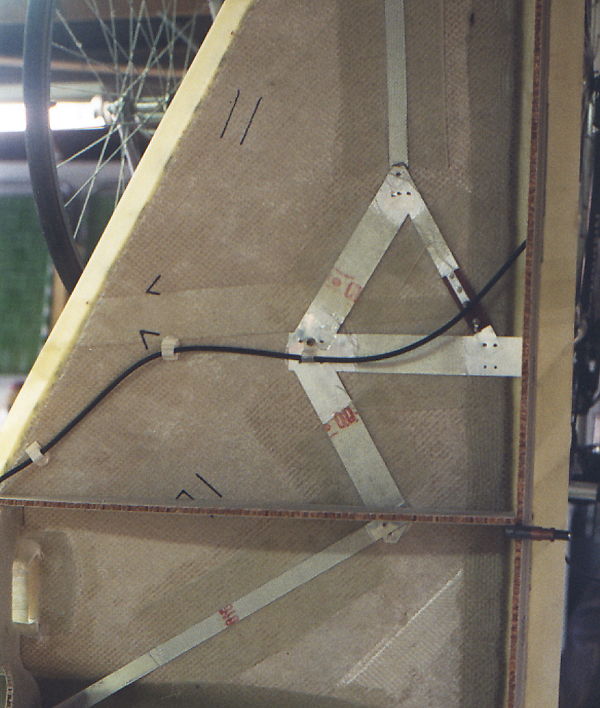

After the Horizontal

Stabilizer is mounted ,the right side of the Vertical Stabilizer is

mounted and bonded to the Vertical Spar and the Horizontal Stabilizer.

Prior to installation of the rib the Communication Antenna should

be installed. The above photo shows the full spread of the

communications antenna. The one used is from Bob Archer and was

glassed into place with single ply bids. As can be seen from the

above photo, it just barely fits. |

|

|

I tried several different mounting arrangements but all

had some conflict. The black marks on the photo above show the

only alternate mounting which would work as well. I picked the above

arrangement since I was concerned that the electrical bonding cable

which will run up the rear stabilizer spar would interfere with the

signal.

|

|

|

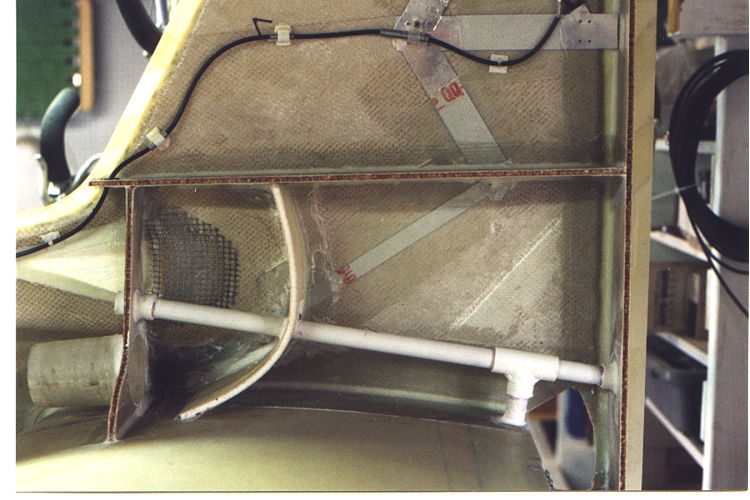

Now if this looks a bit

strange, did I mention that my wife had ask that I install in-plane

plumbing? This shot shows several additions which I have

incorporated. First the plumbing, it's conduit for the electrical

wiring to the rear strobe and trim servos. The idea is to provide

an easy, non-restricted path for running the electrical wiring.

Like the conduit in the wings, this provides a clear path for the

wiring and one which can be serviced in the future. The curved

panel is an air baffle to route the incoming air from the NACA scoop

and through the tube just above the horizontal stabilizer. The

NACA air scoop can be seen just in front of the bulkhead. The

outlet from the scoop is covered by a wire screen to keep unwanted

critters from getting in. |

|

What can't been seen here

is the drain tube which is in the lower corner against the fuselage

wall. This will allow any moisture accumulation to be removed.

Prior to closure, the air box was closed with a prepreg panel and

glassed into place. I closed it out separately because I felt it

would be impossible to get a good seal on the air box with the other

side of the vertical stabilizer. This way I could seal the box

without having to make the airbox airtight within the stabilizer.

Prior to closure I also potted an epoxy-flox mixture over the

antenna connections. |

|

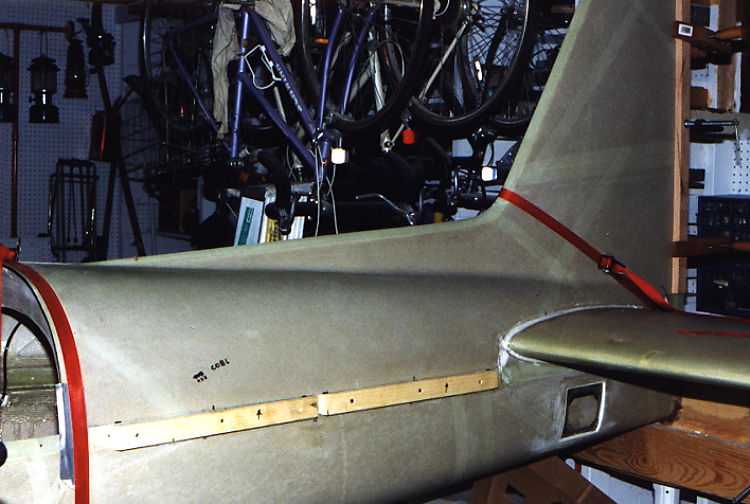

I used a number of

different clamping methods to close out the vertical stabilizer and the

fuselage section. The strap clamps were great for putting

pressure on the area around the bulkhead and for the lower portion of

the stabilizer. The vertical portion of the stabilizer I used

some wood clamps and a 1 x 2 hardwood strip. The wood clamps

worked great because they can be closed in on the same angle as the

stabilizer. The hardwood strip helps keep the sides of the

stabilizer nice and straight with even pressure along the stabilizer

spar. I used matching 1x2 wood strips on the inside and outside

of the fuselage held tightly together with drywall screws to clamp the

fuselage together.  |