Once the wings have been closed and the wing tips installed the same steps are performed for each wing.

|

|

|

The

leading edge will have a glass layup over the joing line between the

top and bottom. The glass will be filled and sanded until the

flow between the top and bottom.

|

|

|

|

|

The

wing tips will require special attention to fill and smooth to fill and

level to the rest of the wing. After the wing is sanded and

filled to a clean surface it will still have substantial pin holes that

even an epoxy coating will not fully cover. The best way I found

to get a truely pin hole free and totally smooth wing was to cover the

entire wing with another layer of glass.

|

|

|

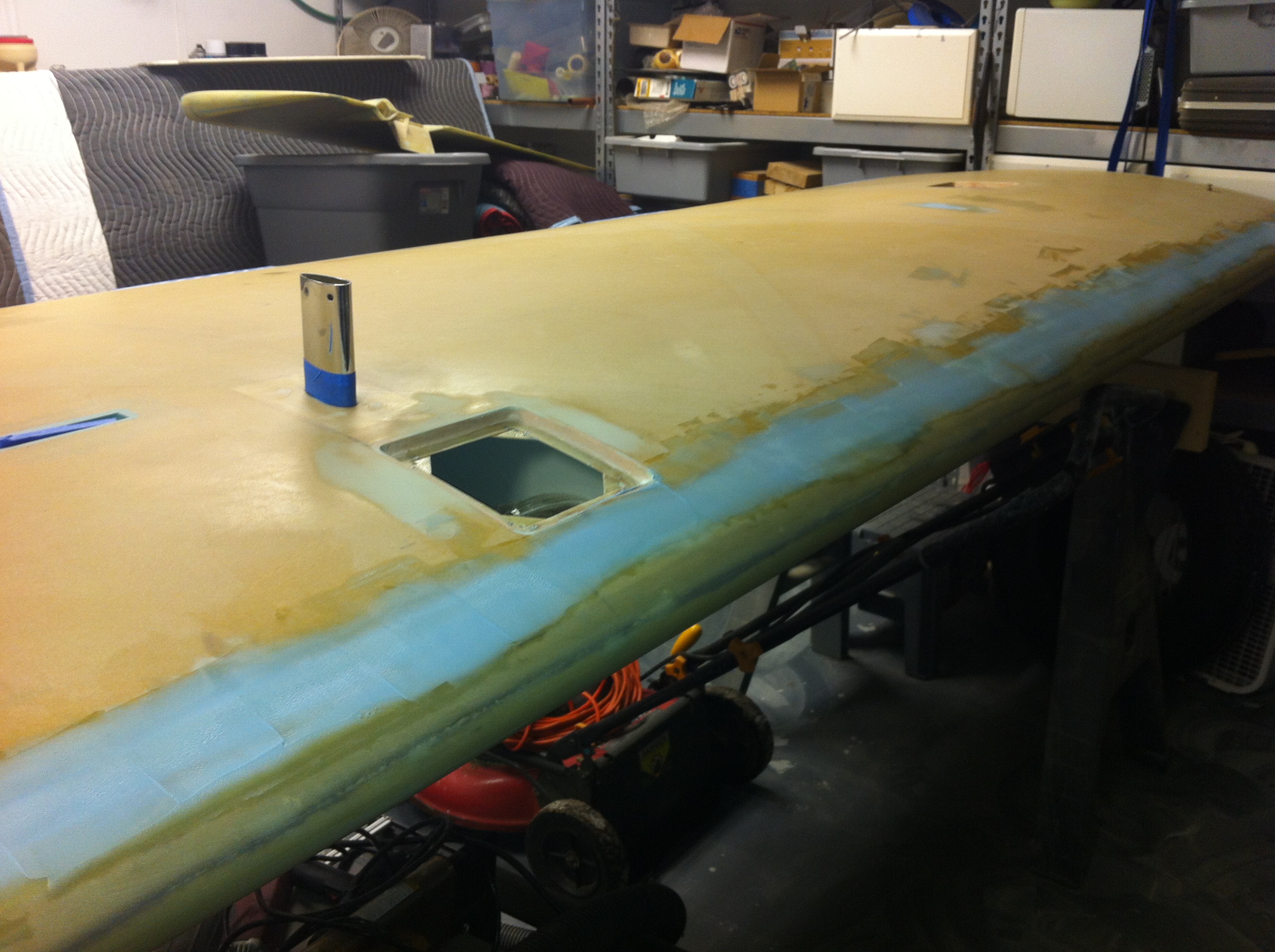

Using

a very light weight (1.5 oz) high fiber count glass the wing is covered

from tip to tip on bottom and top. (This is called deck cloth and

used in the boat building business to cover teak without showing)

Once the glass is covered with a thin layer of epoxy the entire wing

will be sanded again.

|

|

|

|

|

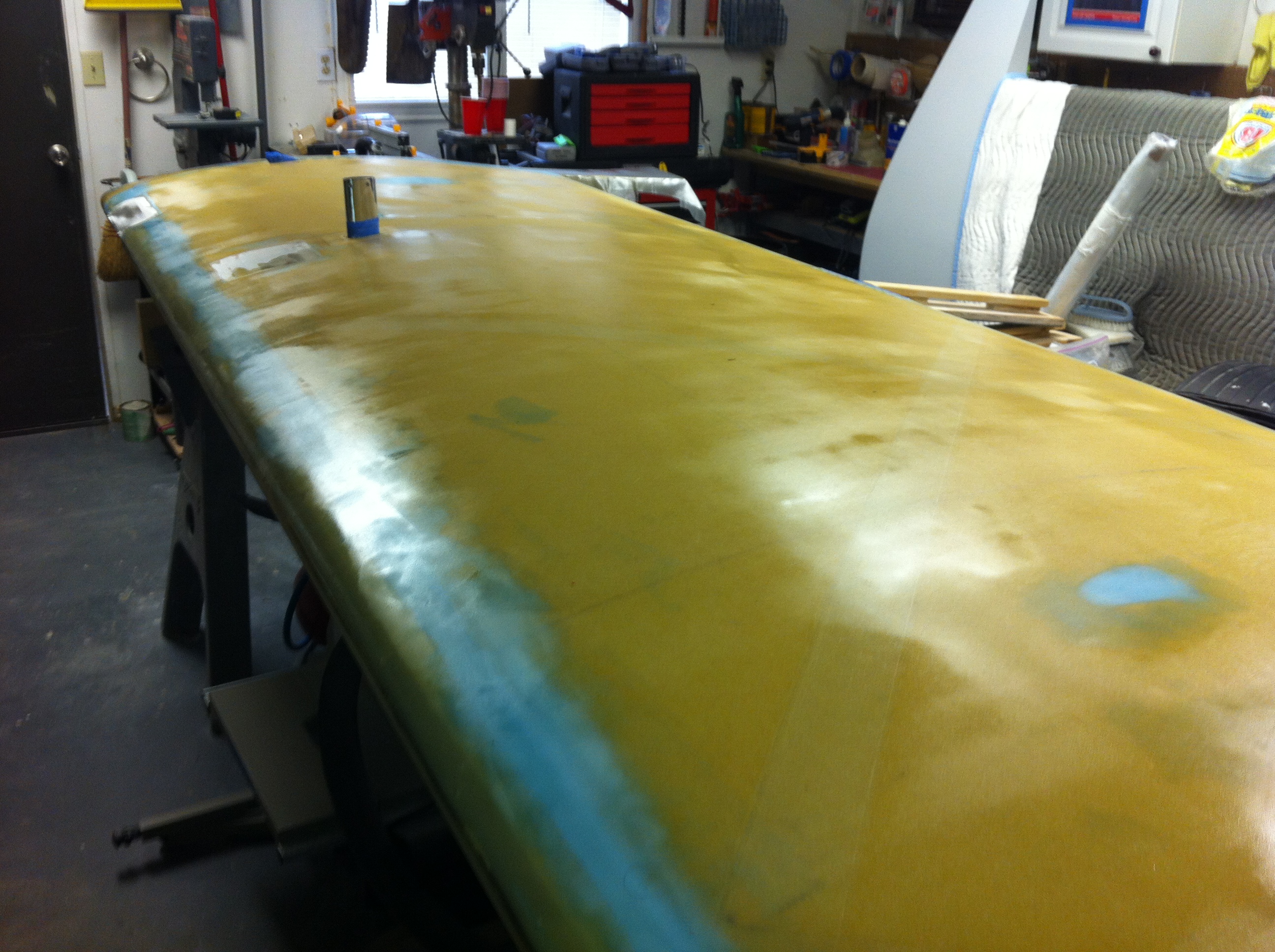

The

glass and epoxy is sanded again using a wide fine grade paper using a

long board. Once the final sanding is complete, the wing would be

primed.

|

|

|

|

|

Multiple coats of primer and sanding between coats produces a super almost mirror like finish on the primer.

|

|

|

|

|

I

did make one major mistake in the wing finish process that I came to

regret. The length of time between priming the wings and the

final painting of the wings was months/years and as a result the final

paint did not bond properly with the primer and I had to repaint each

of the wings. The end result shown below came out good but NOT

great.

|

|

|