| The KIS Cruiser

Wing Spars consist of a Center Spar and individual Wing

Spar's. The Center Spar spans the width of the fuselage and

extends

close to two feet on either side of the fuselage. The Wing Spars

are

each joined to the Center Spar by two large bolts. |

| MAIN

FUSELAGE SPAR |

|

|

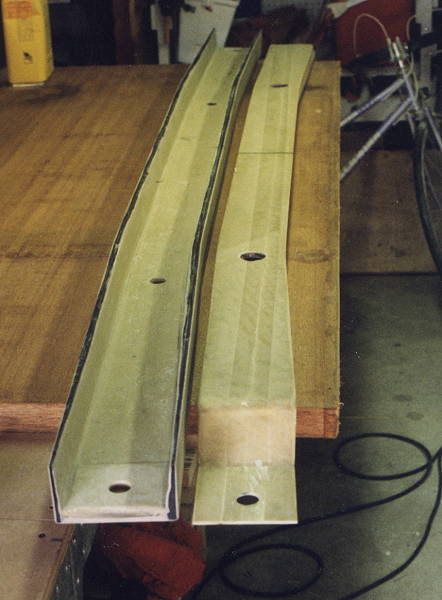

| The above shows the two sections of the Center Spar before

being joined. The ends have been trimmed and the holes for the mounting

bolts cut. |

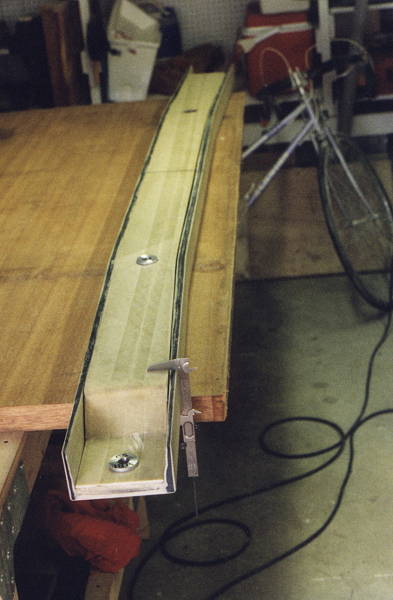

This shows the flange for the bolts. A

substantial amount of sanding is needed to the inside surfaces to get

the two pieces to fit together properly. |

|

|

| Checking the pre-assembled spar for the correct assembled

thickness. |

Spar Clamped to work surface with shims used to level and

remove any twist. Level and check both ends. |

|

|

|

Cutout in the fuselage to receive the finished Center

Spar. The black horizontal line indicates the top of the spar

position. The opening is required to be a bit larger to allow

the spar to slide into position. |

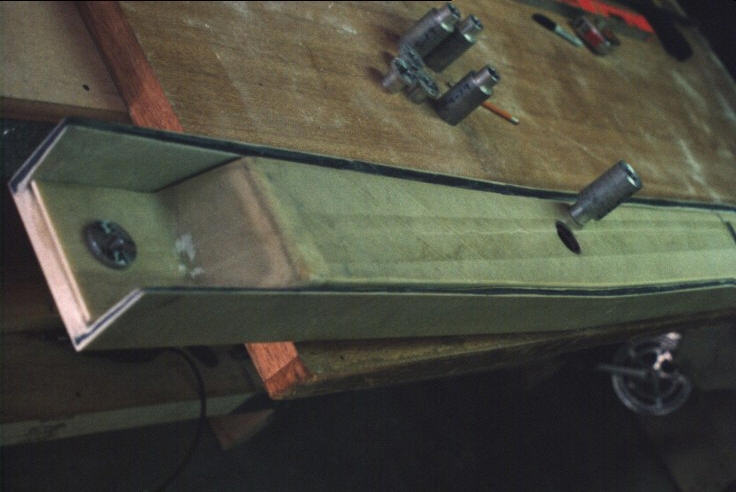

| The main spar show here is installed into the fuselage.

I failed to take photos of that installation process. The

spar must be centered on the fuselage and leveled while the fuselage is

leveled. The spar is installed at a 3 degree angle to the belt

line of the fuselage. Once positioned, it is then bonded and

glassed into place. |

|