| The wing close

out is probably one

of the most

intense sessions of the

building process. There is much that must be done leading upto

the

close process and a great deal that must be completed in a short period

of

time. There are something over 1000 square inches of surface area

that

need to be fully covered with adheasive prior to the close. It's

not

a difficult process but once started has to be moved to completion

without

stopping or the initial adheasive will setup and start curing before

you

can get the wing closed. We started about 10:30 in the morning

and

by 12:15 were completed with the loading of the weight. The

photos

below show much of the advance work that had to be done upto the final

load

of sandbags and cinder blocks. |

|

PS:

This is

the first set of

photos taken with my

new Sony Digital CamCorder using the photo option. They came out really

well

considering no flash was used in a normally lighted garage. These

have

been further compressed to make the resulting file as small as possible

for

web use. Double click on any photo for a larger

display. |

|

The wing bottom is finally ready after my first attempt at

sealing the fuel bay area had to be redone because the initial coat of

Jeffco 9700 cured on me before I could get the second coat on. I

waited a week to sand it down and put on the needed two coats of

sealant. The Jeffco is great stuff but must be mixed in rather

small batches and applied quickly or it will setup in the pot.

The working time is only about 15 minutes. The cure is

quick and the surface is smooth. |

|

This shows the access panel along with the inner fuel bay

bottom. In the right lower corner of the fuel bay you can see the

fuel/water drain at what will be the lowest point in the fuel tank. |

|

Here is a clear view of the lower wing skin which shows

the access panels, fuel bay and sanded areas for close out. The

lower skin is now ready for closure.

The first part of the close process was to wet out the

sanded areas with adheasive between the lines shown.

|

|

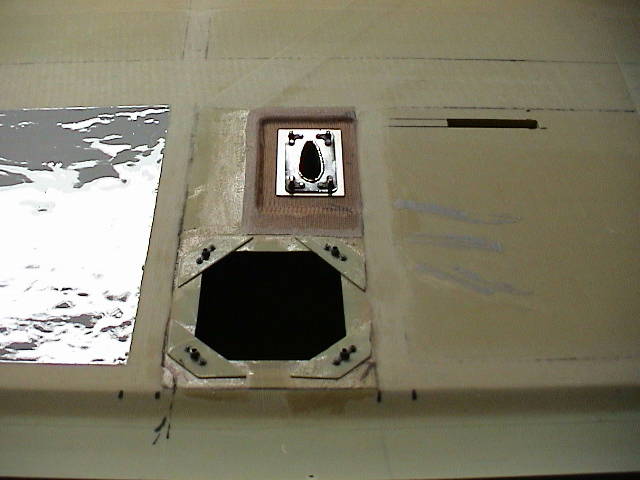

This shows the access opening for the aileron idler arm

and the pitot tube. The area above the access opening is the

bottom mount for the pitot tube. This was installed in a hard

point glassed into the wing. The tube is shimmed under the upper

part to level the tube into the relative wind. The small slot to

the right of the pitot base is the opening for the retractable tiedown. |

|

|

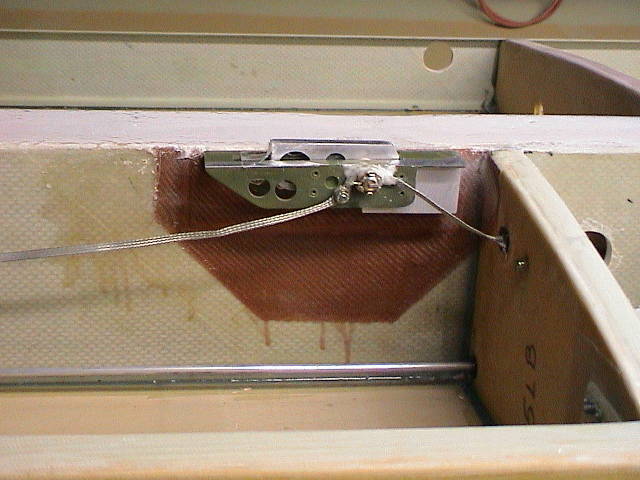

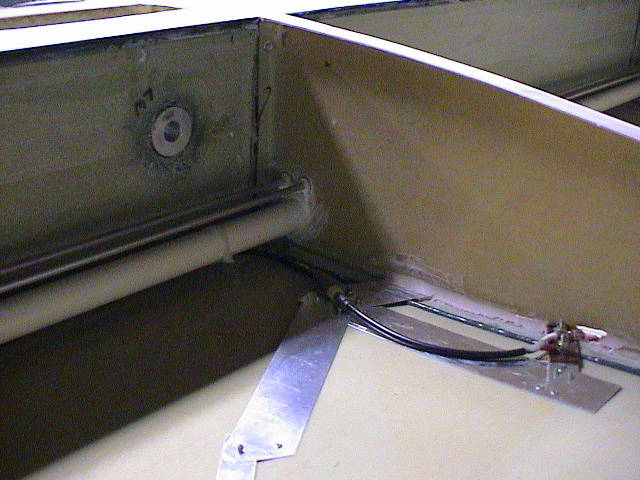

| The photos above and below show the pitot line

and electrical conduit (upper left), spar bolt access panel (upper

right), Navigation antenna installed against upper wing skin (lower

left) and retractable wing tie down (lower right). Note the

braided ground line which runs from the fuel bay filler to the vent

line, elevator idler arm, tiedown, and ultimately all metal ponts on

the wing before return to a common ground point. |

|

|

|

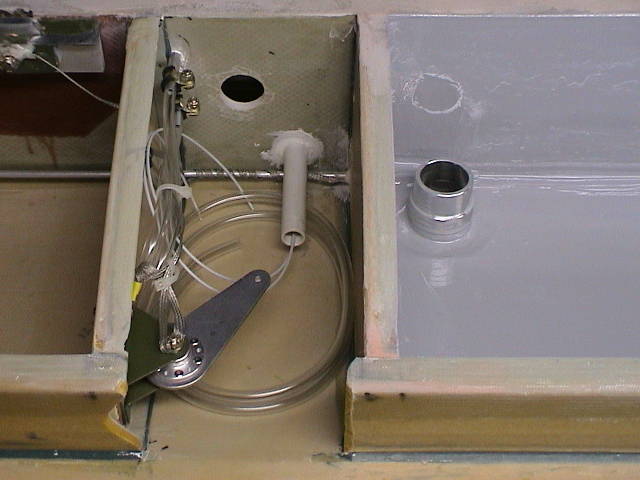

This photo shows the fuel inlet which has a ground wire

attached an runs to the outside of the fuel bay, connects with the vent

line and then to the idler arm. It runs back and over to the wing

tiedown. Inside the opening with the elevator idler arm you can

see the electrical wiring for the pitot heater along with the pitot and

static lines. The flexable pitot lines are already permanently

attached to the aluminum lines through the wing. The tubes are

long enough to extend out the base for installation. A tie point

is provide for keeping them clear of the control arms. |

|

|

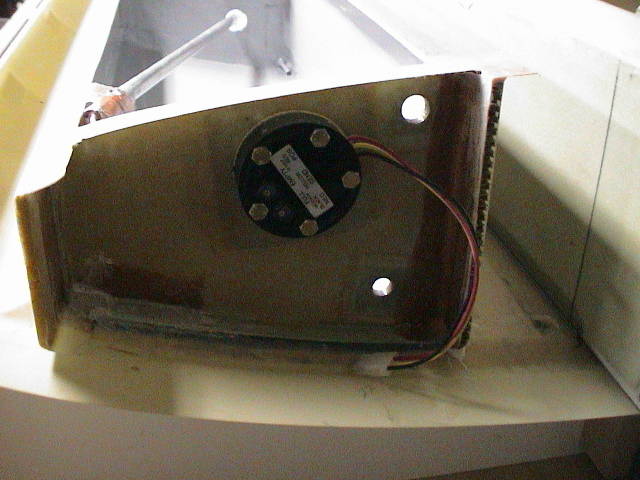

| These shots show the completed and sealed fuel

bays. The (upper left) photo shows the fuel level tube running

though the first two bays. You can also see the vent line between

the first two bays along with the openings for the fuel lines.

The (upper right) shows the full view of the inside wing bays

with nav antenna and fuel bays. The (lower left) shows the fuel

level sensor connection. One important point to remember is to

ream out the fuel connection openings after sealing and before

closeout. The (lower right) shot shows the slosh valve between

fuel bay one and two. |

|

|

|

This shows the connection for the navigation antenna.

I am using the Archer antennas for all my installations.

The are inexpensive and foolproof. I cut an opening in the

rib to slide the side of the antenna arms through. The gap is

then filled with epoxy filler and the cable mounted. the wings of

the antenna are simply pop riveted to the wing skin. This

allows the antenna to be set in the optimum open position. |

|

Here is my close out team with yours truely out of the

shot. My wife, daughter and her long term future significant

other (Nope!) were my only crew. They did a great job and painted

on a wetting coat of adheasive on all surfaces before I laid down the

thicker bead of adheasive / flox required for gap filling and strength.

The pre-wet of both the bottom wing skin and the spar/ribs made

the process much smoother. |

| The next two shots show the wing just before

the skin bottom was placed into position. The adheasive is a dark

gray and can be seen on all surfaces. I put on a very liberal

amount and can only hope that is was enough/not too much. It

thickened well and with the prewet done smoothed out well. Only

time is will tell if the fuel bay sealed out completely. The

joints looked fairly good after the closeout. Some excess was

evident only on the inside spar area. |

|

|

|

Well...it is done. Almost a thousand pounds of total

weight is spread over the entire wing with concentration on the areas

over the spars and the ribs. I was not too happy with what I

could see of the squeeze out at the front spar. There seemed to

be a gap at the leading edge of the joint and that may prove to be a

problem. The opening is too small and long to get any sealant to.

Time will tell. |