|

|

Wing Leak Testing

This should be titled the the ultimate frustration. The process of checking the wing fuel bays for leaks is like hunting for the needle in the hay stack but without knowing how many needles you are going to find. The first step is to try and seal all the intentional openings such as the fuel filler cap, fuel lines, fuel drain, and fuel level guage.

The next step is to hookup a plastic tube to the fuel vent line with a dip well below the vent line and extending well above the vent line. This line must be installed over the wingtip fuel vent and sealed to the connection. Put water into the line to provide a means of gauging the pressure inside the fuel bay. Next, connect a flexable rubber hose to the main fuel outlet line and make sure the connection is sealed. This hose will be used for putting pressure into the system. I found that I could put more than enough pressure on the system by blowing into this hose and then putting a clamp on the hose or inserting a plug into the end.

That was the easy part...or at least should have been the easy part. One of the most difficult problems I encountered was trying to get a good and consistant seal around the water line. I tried tape, clamps, an couple of other methods and still had some tiny little leaks. On one wing, the fuel drain had a leak around the threads. On the other wing, I had a leak around the fuel level sending unit. I had a problem getting the screws on the sending unit to properly tighten so in ended up bonding them in place and bonding around the sending units on both wings. It worked but pray that I never have to remove those fuel sensors.

|

|

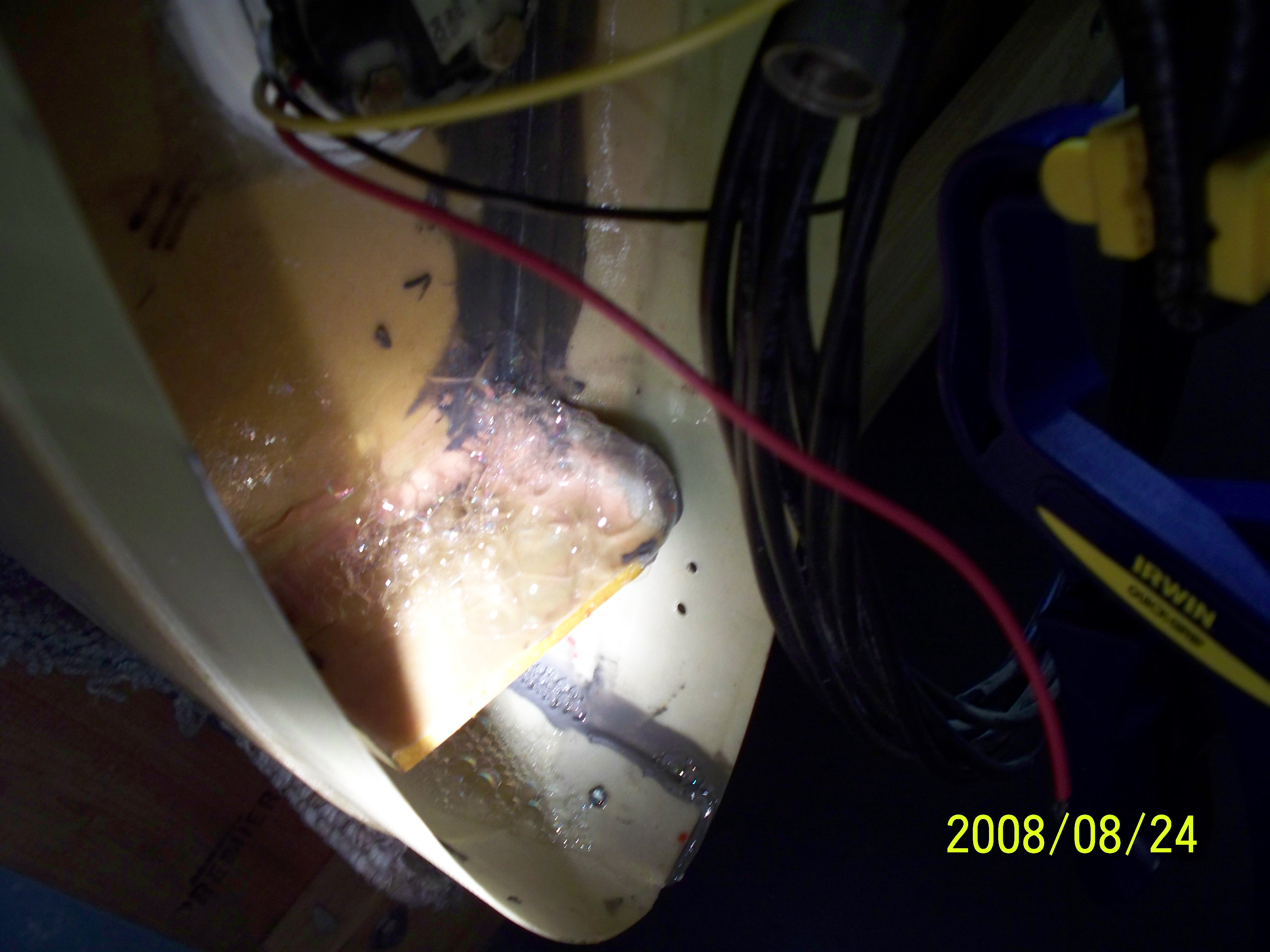

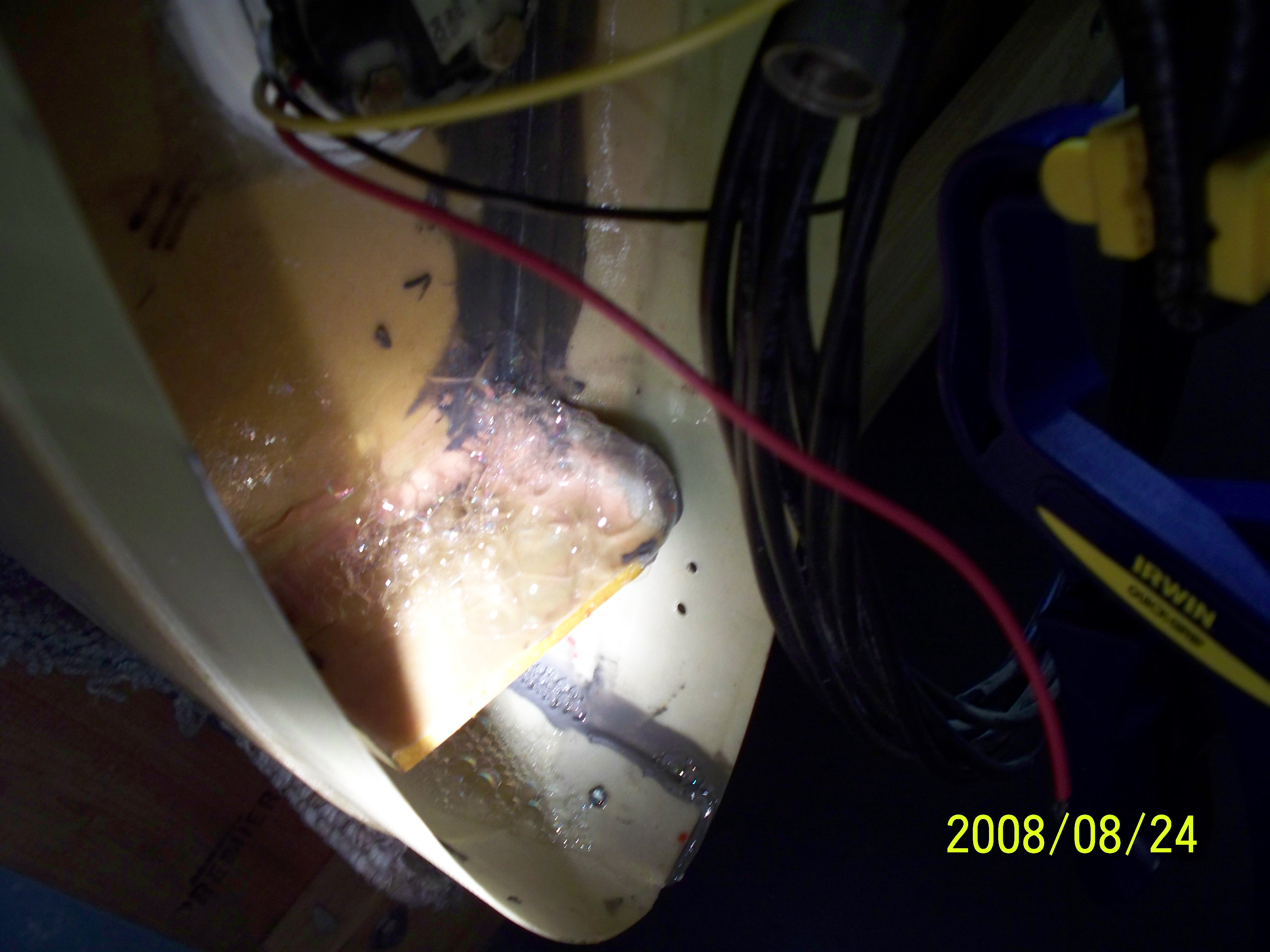

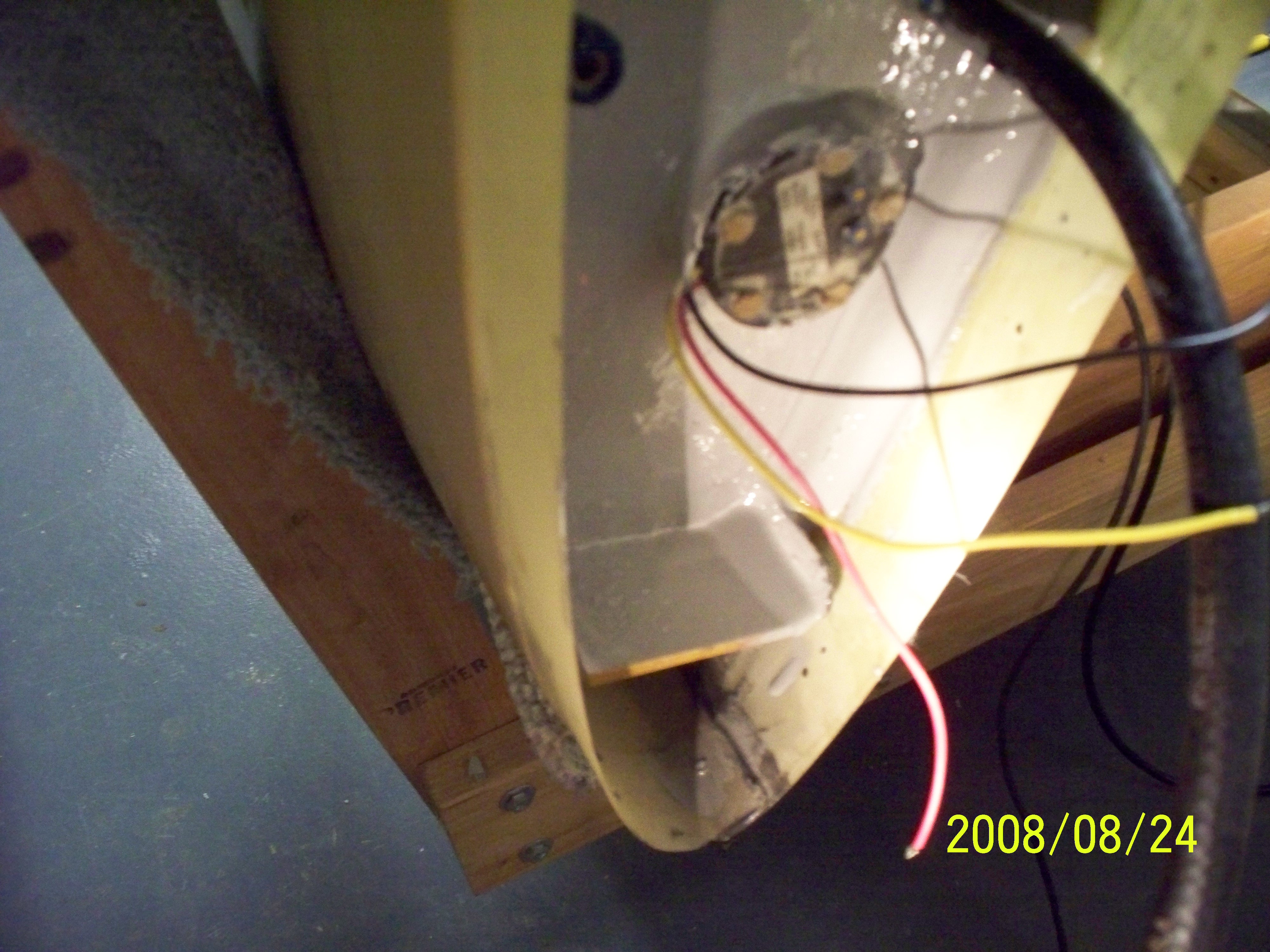

The above photos show what turned out to be the ultimate in frustration. When I performing the leak tests on the left wing, I found several small leaks and repaired them. They include on leak around the fuel sending unit and the fuel drain. I still couldn't find the primary leak even after several days of sealing everything I could think of even though I hadn't found a leak in the areas. Nothing seemed to work. I had initially worked with the leading edge of the wing pointing up. Finally, I determined the leak MUST BE in the back of the fuel bay on the inside of the wing. So...I flip the wing, open inspection holes in the rear spar and seal the inside of the rear bay. Still, no joy and the leak persisted. Once again, I went back over every single joing of the wing. While testing the fuel lines and fuel level sending unit, I did a very liberal spray of the soapy water on all the fittings. NO LEAKS yet again but then I saw them...those tale tale bubbles. They were not coming from the joint between the spar and the wing or leading spart, at least not in the corner where I had previously been looking. No, they were coming from the END of the spar under a fiberglass fillet. I had filled the corners very well and extended the fillet to the end of the spar. The leak and gone under the fillet which ment that as long as I didn't fill the little cup formed by the spar, the bubbles didn't appear.

|

|

As a result, I cleaned out all the joints and resealed them with an epoxy fillet. I then mixed the Jeffco 9700 sealant I used on the inside of the fuel bay and painted the entire end of the bulkhead. I worked and the wing was finally sealed. I repeated the process on both wings. I did find a few more major leaks on the second wing but was able to get them all sealed. I am really glad this is over with.

==========================================================================================

One final thought. After finally completing the sealing of the leaks on the first wing, I again pressurized the wing and waited to see if there was any loss in pressure. I was late in the day and I didn't see any movement so I was very encouraged. Early the next morning before going to work I checked the level and was discouraged to see a very significant drop. I spent the entire day kicking myself for still missing the leak. That night when I got home from work I again checked the level....and found it higher than when I started. I had totally forgotten that the changes in temperature and barometric pressure would have a significant effect on the level of the water. I left the tank pressurized for the entire week and NO LEAKS.