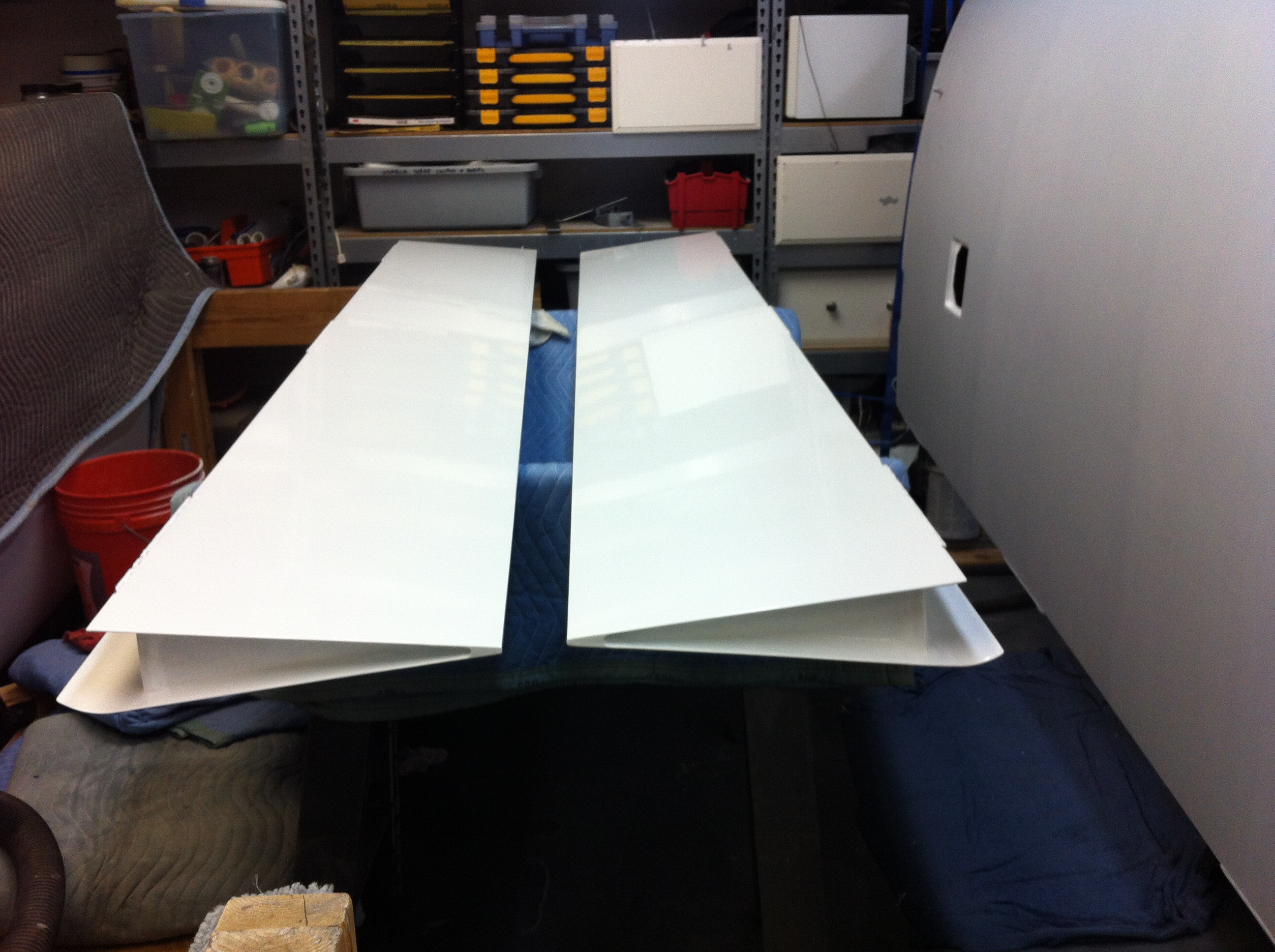

| Part 3 - Extending the trailing edge of the flaps by 1/4

inch to

align with Ailerons. |

|

Sometimes, no matter how careful we are something doesn't

work out exactly right. I checked my measurements several times

and I still can not determine why the trailing edge of the flaps on one

side did not properly align with the ailerons. Both Ailerons

aligned almost perfectly with the wing tips and only required slight

trim on the tips. This flap was the exception. |

|

I realized this before closeout on the flap and inserted a

strip of fiberglass between the trailing edges of the flaps. This

strip extended about 1/2 inch beyond the edge of the flaps. I put

the strip in to ensure that the finished tip would be consistant in

thickness to the ailerons when trimmed. |

|

I used a metal straight edge, covered with tape and

clamped to the flap to form one side. I then packed the gap

between the straight edge and the insert. After cure, the

straight edge was remove, any gaps filled and the process was repeated

for the other side. After final cure, I sanded the fill to a

consistant taper alway to the edge. The final trim of the

trailing edge was done during the preassembly.

This worked great.

|

|

The extended edge was almost 1/2 inch wide. I did

not sand it down until I had mounted the wings, ailerons and flaps

during the preassembly. I then sanded the wing tip to match the

edge of the aileron once everything was properly aligned. |

|

The

flaps were one of the first components that were fully sanded, primed,

and painted. But the process was extended over a long period of

time and while the primer went on perfectly and produced a surface that

looked like paint. The problem was the length of time between

prime and paint was more than a year and the paint failed to properly

bond to the primer. The result was paint that easily peeled

off. I ended up having to sand the paint off and repainting.

|

|

The

completed and installed flaps can be seen in the three surrounding

photos. The seal between the wing and the top of the flap turned

out tight with no gaps. They go up and down without any binding.

|

|

|