Tri-R Technologies

TR-4

BUILDER'S

MANUAL

This Builder's Manual is NOT the official manual

as published by TRI-R Technologies.

FUSELAGE

Quick Links to Wing Assembly Sub-Sections:

SPAR

PREPARATION

LEVELING

AND FIXTURING

SPREADER

STICKS

TEMPORARY

FITTING OF THE FUSELAGE TOP

FIREWALL

FIREWALL

FRONT FACE

ADDED REINFORCING IN FIREWALL AREA

STATION

139.5 BULK HEAD

STATION

180.5 BULKHEAD

MAIN

SPAR AND OUTBOARD SPAR PRE ASSEMBLY

REAR

SPAR

MAIN SPAR LOCATION AND INSTALLATION

POSITIONING

SPAR

MOUNTING LAMINATIONS

MAIN

GEAR BOX REINFORCEMENT

SEAT

FRONT BULKHEAD & CONTROL MOUNT

FUSELAGE

BELTLINE

CONDUITS

FRONT SEAT BACK ASSEMBLY

REAR

SEAT BACK INSTALLATION

CONTROL

CONSOLE - FRONT SEAT AREA

ELEVATOR

IDLER BELL

CRANK

SEAT BOTTOM ASSEMBLY

FRONT

SEAT

REAR

SEATS

FRONT

FLOOR ASSEMBLY

STICK

LINKAGE ASSEMBLY

FLAP

HANDLE ASSEMBLY BRACKET

AILERON

IDLER INSTALLATION

FLAP ACTUATION TORQUE TUBE INSTALLATION

RUDDER

IDLER LEVER INSTALLATION

HORIZONTAL

STABILIZER

INSTALL

RUDDER POST

ELEVATOR AND PUSH/PULL ROD

INSTALLATION

RUDDER CABLE ROUTING AND

INSTALLATION

MAIN

GEAR INSTALLATION

BRAKE

LINE INSTALLATION

FIN

RIGHT HALF INSTALLATION

INSTALL

LEFT FIN HALF

HANGING

RUDDER

INSTALLATION

OF FUSELAGE TOP

BAGGAGE

AREA BACK PANEL

DOOR

PREPARATION

WINDOW

INSTALLATION

DOOR

LATCH ASSEMBLY

MOUNT

DOORS

LATCH

PLATE INSTALLATION

AIR

STRUT INSTALLATION

REAR

WINDOWS

INSTRUMENT

PANEL

WINDSHIELD

MAIN GEAR BOX

REINFORCEMENT

The primary reinforcement of the landing gear "box" area is the multiple

layers of BID applied in the high load areas. These are integrated into the

rear seat front bulkhead which is bonded to the center of the main gear box.

-

Fit and tack the bulkhead into place on top of the landing gear recess.

-

Fillet the edges of the bulkhead.

-

Make up Two, 2 inch wide, 2 ply BID tape and apply to each side of the bulkhead.

-

Apply 10 layers (two sets of 5 ply) in the area for the gear mounting bolts,

overlapping up the sides of the fuselage wall and the faces of the seat bulkhead

as shown on figure XXX. Stagger the overlaps of these two sets of plies slightly

to taper the edges.

SEAT

FRONT BULKHEAD & CONTROL MOUNT

-

Cut the front seat forward bulkhead from the supplied flat panel material,

cutting to the outline provided.

-

Insert 1/4 inch plywood hard points as per figure XXX and cover with two

ply bid. A minimum of one inch overlap.

-

Bond the bulkhead into place with 2 ply BID on both sides at STA. 31

(30). Make sure the bulkhead is square in the fuse and is vertical

in alignment.

-

Tack in place a strip of laminate 2 inches wide, on the top edge, forward

side of bulkhead 31. This will form the support for the front seat bottom,

at the front of the seat bottom.

-

Make enough 3" wide prelam strips to bond the inside and top edges of this

support strip. Fillet the inside edge and round and fill the top edge to

give a smooth surface for the pre lams to form and bond too.

FUSELAGE BELTLINE

CONDUITS

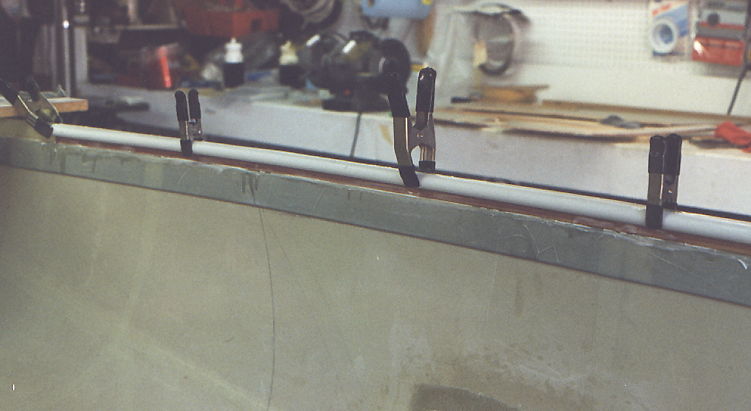

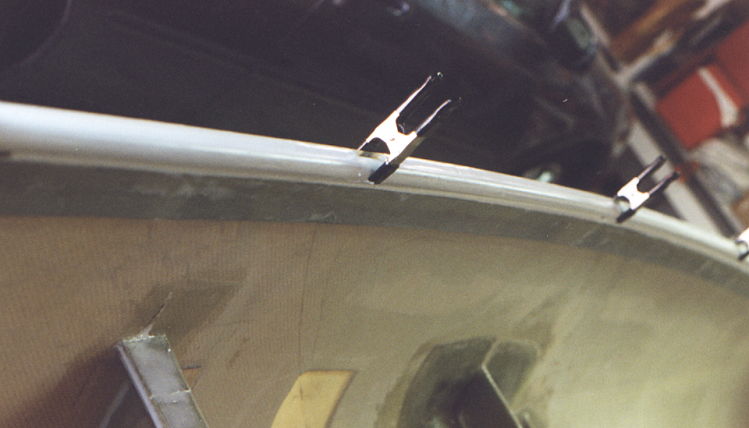

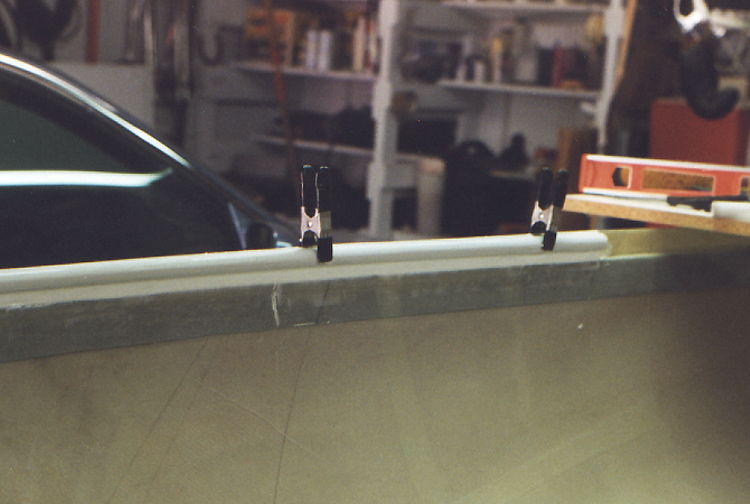

Two sections of plastic tubing shall be bonded to the fuselage in the

''belt-line'' area providing a conduit for antenna coax and electric lines.

This also provides added stiffness along the edge of the cockpit opening.

-

Use the supplied PVC tubing, roughen and tack in place from station 24 to

station 95 with dabs of 5 minute epoxy.

-

When the tubing is secured in the desired location, fill in the edges on

each side of the tube with dry MICRO paste and overlay with 4 ply BID tape

full length. Allow a generous overlap in the bonding areas, 1 inch if possible.

Green trim any overhanging BID in areas where it might interfere with mounting

the top skin. Review figure XXX for approximate location of the tubing and

bonding BID. This tubing should be installed before any other structural

bonding will limit access to this location.

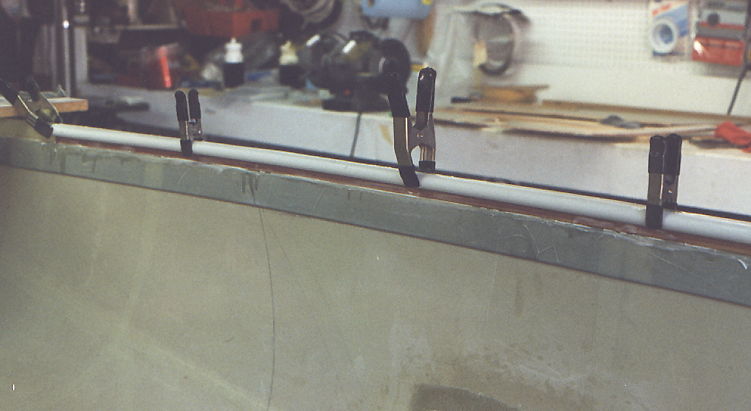

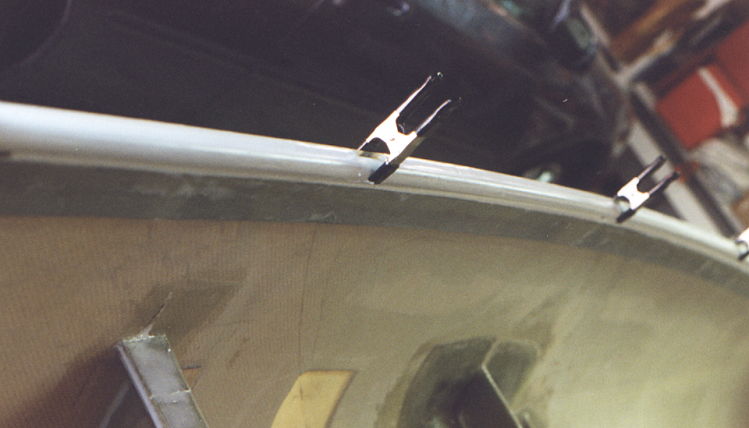

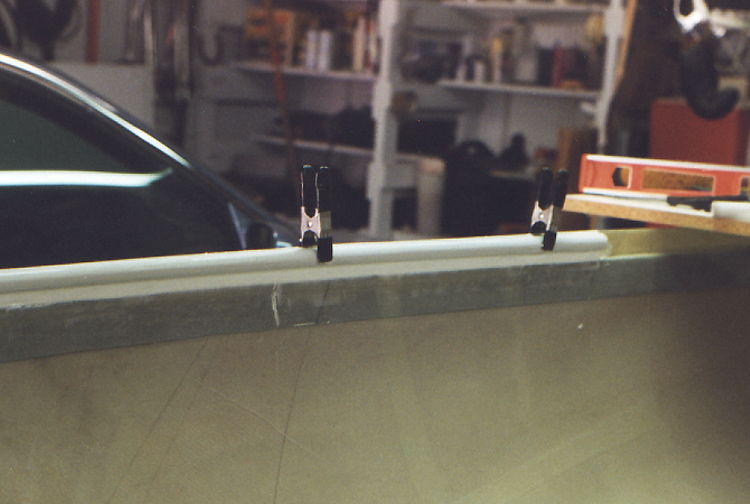

Figure 131-133: Electrical Conduit Installation

|

|

|

| Tacked into place with 1/4 inch plywood spacer used to position

conduit level with the 0.0 waterline. |

Micro mix used to fill the space between conduit and fuselage

side on top and smooth transition into longeron. |

Sand and layer a two ply bid over and around conduit finishes

and provides very strong edge. |

FRONT SEAT BACK

ASSEMBLY

To help facilitate the installation of the front seat back and the rear seat

back, the control console sides, (4 pieces), are cut following the outlines

on the prepreg panel.

The lower end of the back of the front seat is mounted roughly three inches

aft from the rear edge of the center main spar.

-

Cut a 3 inch wide strip of prepreg panel and bond it on to the aft edge of

the center main spar using the forward console sides as a guide to the correct

angle. See figure XXX.

-

Tie this 3" wide strip to the main spar center section with a 2 inch wide

2 ply pre wetted BID strip. Fillet slightly to make a smooth finish for the

bid. (This must be a strong joint).

The front seat back will be installed to the back edge of this strip, and

angled back to where the seat back joins the upper side rail at stations

55.

-

Cut the seat pack panel from the proper section of standard prepreg panel

and fit it into position.

It is recommended that this seat back have two cut out panels to permit a

section of the seat to move forward for loading back seat passengers. A

continuous panel would be lighter and more rigid, but access to the rear

seat would be limited.

-

Cut the panels away to the configuration shown in figure XXX, and fill the

raw edges of the honeycomb panel with a dry MICRO paste. Note how the side

edges are angled to allow the bid to move from one side of the panel to the

other side.

-

Use clear tape or plastic (acetate is best) to provide a "parting" surface

for the flanges which will be added to the moveable panels.

-

The flanges shall be a minimum of 4 plies thick with about 1/2 inch overlap

to prevent the seat panel from swinging back under seating load. Apply two

ply’s to one side, bringing them up onto the top, and then apply the

other two ply’s on the top side overlapping the bottom ply’s. See

figure XXX.

-

The top edge of the seats shall be stiffened with some carved foam, overlaid

with pre-wetted BID.

-

The center section shall be reinforced with a section of plywood with BID

on both surfaces (see figure XXX). Overlap the folding panels about 1" to

insure a positive stop under heavy loading.

-

Fasten the folding seat backs at the bottom with a strip of locally procured

hinge on each panel using #8-32 flat head screws.

-

Tack into place with dabs of 5 minute epoxy.

-

Bond the lower edge to the 3 inch wide angled section bonded to the center

main spar with two ply, 3 inch wide wetted BID on each side.

-

Bond the seat edges to the fuselage inner wall with 2 inch wide BID both

sides. Read the next instruction before doing this step.

-

The load bearing points of the top edge of the seat back shall be reinforced

with a gusset of plywood covered with at least 3 layers BID both sides, to

keep the backs supported under heavy seating loads. If the seat back has

been left at its factory height, the gussets should be installed after the

top fuselage section has been installed.

REAR SEAT BACK

INSTALLATION

-

Cut the rear seat, back panel from the prepreg following its respective outline,

and fit it into position (bottom at station 78 and top at station 86).

The center section of the rear seat back may be modified to provide easier

access to baggage etc. by cutting and hinging a section of the seat back.

Make one large folding piece with the bottom ending 1" above the elevator

hard point that is to be installed. Follow the same procedures as in the

front seat back fold downs fabrication. Allow at least 3 inches of material

at the fuse edges to maintain strength as this seat back is a structural

support. See figure XXX.

-

Add a hard point for the elevator idler bracket in the location shown in

figure XXX. Use 1/4 inch plywood, cutting away one surface of the panel and

inserting the wood section.

-

Close out with a four layer BID patch with at least a one inch overlap around

the perimeter of the hard point.

-

Install the seat back with the bottom edge at station 78 and the top edge

at station 86. "Tack" the seat back in place with 5-minute epoxy, and verify

the location while the epoxy cures.

-

Fillet all edges. Bond the seat back assembly in place with 3 inch wide 2

ply BID. (see figure XXX).

-

Insert a 1 1/2 inch square hard point on each side in front of and near the

bottom of the seat back on the outside fuselage skin, for the rear seat lap

belt attach points. See figure XXX.

-

Apply a 4 ply BID on the outside and inside of the fuse’ with at least

a 1 inch extra overlap over the seat belt hard point.

-

Cut a 3 inch wide strip of the same honeycomb panel as used for the seat

back, and install it to stiffen the upper edge of the seat back (see figure

XXX). Follow the same procedures as with the front seat back as to installing

support gussets and the fuse’ Top.

-

Fabricate a 1 inch wide angle of 4 ply BID to serve as the rear support for

the removable seat bottom panels. Use a piece of 2" angle aluminum, purchased

from the local hardware store, to use as a mold for the angle lam. (apply

a small amount of wax to the aluminum before appling glass and resin.)

-

Lay out a straight line from the seat forward support ( this is the stiffener

bonded onto the top of the landing gear box), over the rear spar, to the

bottom of the rear seat back, to establish the height for attachment of this

angle to the seat back. Bond the prefabricated angle into position onto the

seat back front surface.

CONTROL CONSOLE

- FRONT SEAT AREA

Many of the control functions are mounted to and/or routed through - the

center "console" . The console has the form of a "tunnel" that runs from

the front seat forward edge to the rear seat back and is boxed up between

the seat areas on each side. The panels should have been cut out of the prepreg

material in a preceding section.

-

Test fit the panel sections into the location shown and do any fine trimming

which may be required for a proper fit . The tunnel width will narrow from

a 4 inch outside width in the front seat area to a 3.5 outer width at the

rear seat back.

The rudder cables will be routed against the walls of this tunnel section

to minimize friction and avoid interference or conflict with any of the other

functions in the tunnel. To accomplish this, the cables will be run inside

hard nylon tubing attached to these walls.

-

In the front section, the nylon tubing should be held straight by inserting

1/8 in dia. rod into the tubing while the nylon tube is bonded in position

on the inner wall with an overlay of 2 ply pre-wetted BID tape (Extend roughly

3 inches of free end of this tube forward of the panel, through the seat

forward bulkhead).

In the rear seat tunnel area, a groove will be cut on the inner surface of

each side panel. The plastic tubing section will be bonded into the side

panels, to carry the rudder cables through this area with low friction and

protected from damage or jamming.

-

The locations of this channel will be marked on the second section console

sides. Verify that this line is continuous and straight, and will just clear

the upper surface of the center main spar cut out, and the cutout for the

main gear box. Also check that the line is directed in a straight line which

will project aft to the level of the rudder bell-crank.

-

Cut away a strip of the inner skin about 1/4 inch wide, and remove core material

along the cables path. Fit the supplied lengths of nylon tubing into these

grooves and bond in place with thick MICRO paste. Close out the open face

with a one inch strip of 2 ply BID.

Several "hard points" will be installed in each panel side. ?

In the forward section, there are two for mounting bolts for the flap lever

quadrant ( on the left side panel), and two more hard points for the inner

lap belt attach points for the front seat belts (one on each side panel).

-

Use segments of the 1/4 inch aircraft plywood for the core fillers. The hard

points for the flap brackets should be 1" square. See figure XXX for the

locations of these "hard points".

-

The hard points for the seat belts should be a minimum of 2" square. These

hard points are a critical item. These areas should be covered with 8 layers

of BID. Make sure that each layer has a minimum overlap on all three surfaces

of 2 inches. A tapered overlap will spread the load more evenly and present

a better appearance if neatly accomplished. The 2 inch overlap is MINIMUM

for any layer.

ELEVATOR IDLER BELL

CRANK

Fabricate from channel and mount to seat back

The desired routing of the elevator push-pull rod, and the rather extreme

length of this rod assembly suggests the value of a two piece push-pull rod

assembly, with an idler bell-crank located behind the rear seat assembly

. This idler assembly will stabilize the long push-pull rod, and allow the

path to be broken into two sections with a good stabilizing point near mid

span. This idler bell-crank also establishes the desired ratio of elevator

travel relative to stick travel. The bell crank slightly amplifies the travel

by setting the shorter leg of the idler on the forward side hooking into

the stick push rod. The longer, aft arm of the linkage hooks to the push

rod leading to the elevator control arm. The kit supplies high quality rod

ends for these joints to minimize friction and end play in the linkage .

-

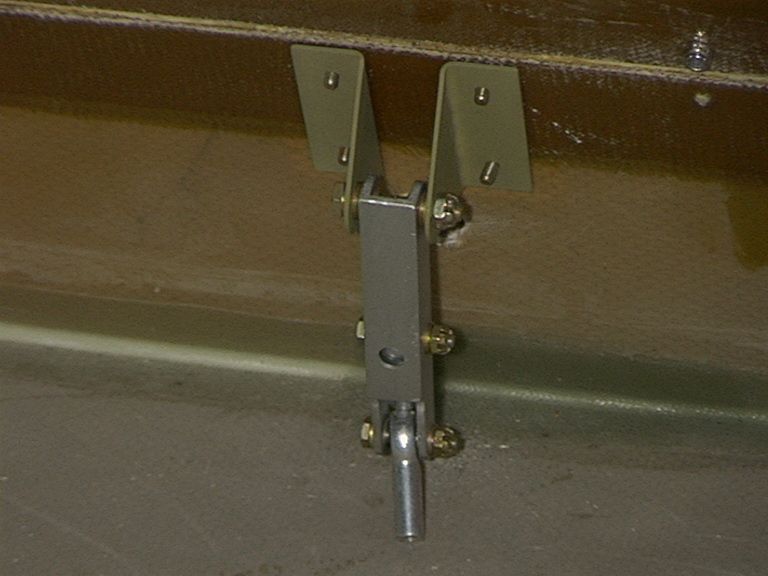

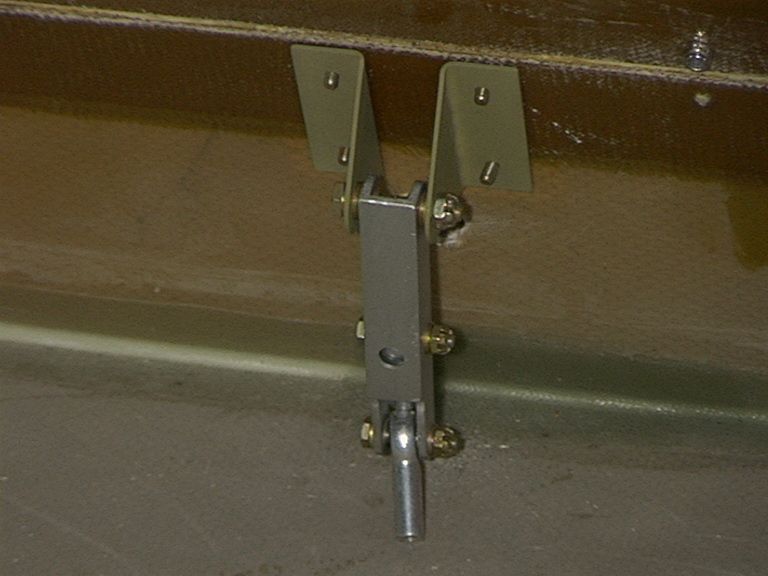

Use figure X-9 as a guide, and fabricate the elevator idler bell crank from

a piece of the furnished aluminum "C" channel.

Figure -9, Elevator Idler Bell Crank.

-

Use the rod ends from the push rods to establish the number of washers to

provide a good fit in the channel sections as shown in figure X-9.

-

Insert the bushings in the pivot end of the idler lever, and use the assembly,

with the mounting angles (part KS-3 ) to aid in drilling the mounting holes

(4) for this assembly. Make sure the holes are aligned square to each other

and the bell crank to preclude any binding.

-

Countersink these holes from the forward surface of the rear seat back and

install the assembly using the 4 flat head #10 - 32 screws supplied (MS2469lS56).

(See figure XXX as guide for these operations.). Four countersunk washers

(A315-017-24A) are also supplied for the flat head bolts selected for the

idler mounting area to minimize "fretting erosion" of the composite

material.

|

|

Elevator Idler arm show on bottom.

Cut from aluminum "U" channel. |

Elevator Idler shown mounted on back of

rear seat. |

SEAT BOTTOM

ASSEMBLY

The seat bottom can be tailored to individual requirements, but the enclosed

instructions describe the method which has worked well on the factory airplane.

The seat panels should be fabricated from the 1/4 inch standard panel material

supplied, or any other similar core material desired.

FRONT SEAT

The front seat bottom panel position is established as a straight line between

the top edge of the panel which forms the front of the seat "box" (station

31 bulkhead), back to the top surface of the center main spar. The left and

right seat bottom panels will be separated by the control tunnel between

the two front seats.

-

Draw a line on the outer faces of the tunnel, and the fuselage inner walls,

and add seat support in the form of "glass" angles formed from about 3 layers

of prelam tape. (use angle aluminum as a mold for the support lams).

-

Make the seat bottom core section a little oversize, (read the next instruction)

and trim to fit.

-

Cut through one skin of the panel in two places. One place about 3 inches

forward of the aft line so this part of the seat can sit flat on the spar,

and again along the edge of the forward support panel so the seat can be

bent flat under the passenger knees.

-

Reinforce with one ply BID overall on each surface and an extra ply of BID

tape at the bends.

-

Cut a generous opening in the front edge of the seat to allow full control

stick travel, and dress the edges of the opening with flox.

-

Trim the edges of the panel to fit closely into place against the tunnel

sides in the center, and the curved fuselage sides on the outer edges, to

keep it from shifting position while in flight.

-

It is desirable to hinge these seat bottom panels at the rear edge to provide

access to the control mechanism, and to provide storage space beneath the

seat . Reference figure XXX to clarify any questions.

REAR SEATS

The rear seat bottom placement is also somewhat controlled by the height

of the panel installed for the seat front (on top of the gear "box"), and

the location of the "glass" angle mounted to the seat back. The location

of this seat bottom panel is rather non critical since there is a surplus

of head room in the rear seating positions. A higher seat bottom will provide

more storage space beneath the seat, and also provide better visibility over

the pilot and front seat passenger. The fabrication of this panel should

closely follow the procedure used for the front seat, With a higher seat

placement, a bench configuration could be used in the back seat as long as

adequate seat belt provisions are supplied, and total back seat loading does

not exceed 340 lbs.